Reducer Gearbox

Delve into our diverse array of reducer gearboxes, meticulously crafted to cater to a multitude of applications across various industries. At the heart of our offering is the promise of enhanced torque, precision in speed control, and the smoothest power transmission, ensuring you discover the ideal solution for your specific needs.

In choosing our reducer gearboxes, you’re not just getting a product; you’re gaining a partner dedicated to enhancing the efficiency and productivity of your operations. Trust in our expertise to elevate your mechanical systems to new heights of performance.

How Does a Reducer Gearbox Work?

A reducer gearbox, also known as a speed reducer gearbox or a gear reducer gearbox, functions as a mechanical component that reduces the speed of an input power source, usually an electric motor, while simultaneously increasing the torque. This process is crucial in various applications where it’s necessary to adapt the speed and torque of a motor to the requirements of a specific task or machinery.

Mechanism of Operation: The core mechanism of a reducer gearbox involves a set of gears. The input shaft is connected to a high-speed gear, which engages with lower-speed gears. As the power is transmitted through these gears, the speed reducer gearbox effectively lowers the rotational speed of the output shaft while increasing the torque. This change in speed and torque is achieved through the gear ratio, determined by the size difference between the input gear and the output gear.

Types and Variations: When discussing gear reducer vs gearbox, it’s essential to understand that a gear reducer is a type of gearbox designed specifically for reducing speed and increasing torque. There are various types of gear reducers, such as planetary, helical, and worm gear reducers, each with unique characteristics suited for different applications. For instance, a worm gear reducer provides high torque reduction and is often used in applications requiring compact size and smooth operation.

Applications and Benefits: The applications of a speed reducer gearbox are extensive, ranging from conveyor systems to automotive transmissions. They are crucial in any scenario where it’s necessary to adapt the motor’s output to the needs of specific machinery or equipment. The use of a gear reducer gearbox not only provides the necessary torque and speed adjustments but also contributes to the overall efficiency and longevity of the system by reducing the strain on the motor and other components.

In summary, the reducer gearbox is an essential component in various mechanical and industrial applications, providing a means to adapt the speed and torque of motors to suit specific requirements. Its operation relies on a set of gears, and its design varies based on the application, emphasizing the importance of understanding the differences and applications of gear reducers in comparison to standard gearboxes.

Ergebnisse 1 – 30 von 113 werden angezeigt

-

VRV035 Series Worm Gear Reducer

-

EPSRV250 Heavy-duty Worm Gear Reducer

-

EPSRV130 Worm Gear Reducer

-

EPSRV70120 Series Worm Gear Reducer Helical Gear Reducer

-

TAER Series High Precision Planetary Reducer

-

TVBR Series High Precision Planetary Reducer

-

TABR Series High Precision Planetary Reducer

-

EPSRV138 worm gear reducer

-

EPVRV103 Worm Gear Reducer

-

EPVRV040 Worm Gear Reducer

-

EPFRV030 Worm Gear Reducer

-

Roller Press Planetary Gearboxes

-

Brick Machine Gearboxes Gear Units

-

Bucket Wheel Stacker Reclaimer Planetary Gearboxes

-

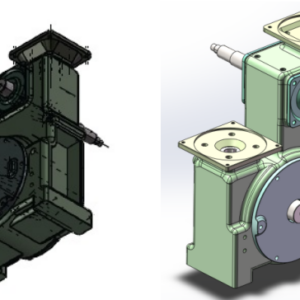

Gearboxes for Steel Plate Flip Machine

-

Gearboxes for Aluminum Rolling Mill Coilers Decoilers

-

Three Rings Reducers

-

Large Crane Gearboxes for Metallurgy & Hydropower

-

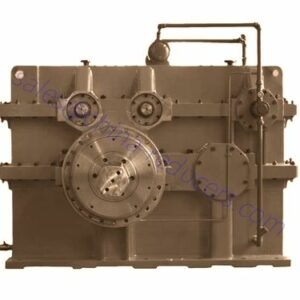

Main Drive Gearboxes for Bar & Wire Rolling

-

QJY/QY Series Crane Gearboxes/Hardened Gear Reducers

-

Flying Shears for Bar & Wire Rolling

-

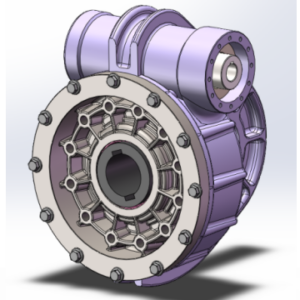

High Precision Planetary Gearboxes

-

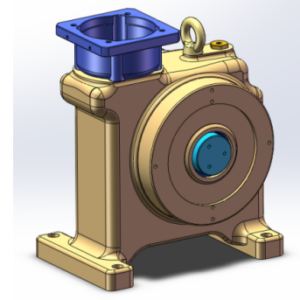

WB Series Micro Cycloidal Reducers

-

X/B/JXJ Series Cycloidal Reducers

-

NGW Series Planetary Gearboxes

-

P Series Planetary Gearboxes

-

EP606L2,L3 WHEEL DRIVES(606W..V)

-

EP402T2-**-WO-** TRACK DRIVES

-

EP410T3 TRACK DRIVES (GFT50T3)

-

EP407AT2, AT3 TRACK DRIVES (GFT26T2,GFT26T3)