ENGRANAJE

-

PLANET CARRIER

-

RING GEARS

-

Ever-power produce all kinds of helical ring gears

-

Differential Gears

-

Spur gears and Helical gears

-

WORM GEARS & WORMS

-

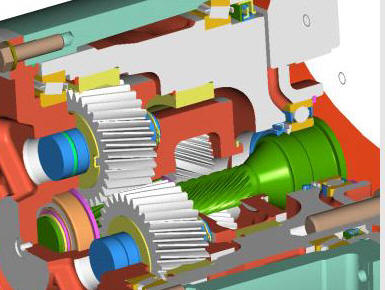

Bevel Gears and Spiral Bevel gears

-

Brazo de torsión

-

Universal Joints

-

Steering joint Assembly

-

Industry Drive Shaft

-

Trcuk driveline / Transmission shaft for Trucks

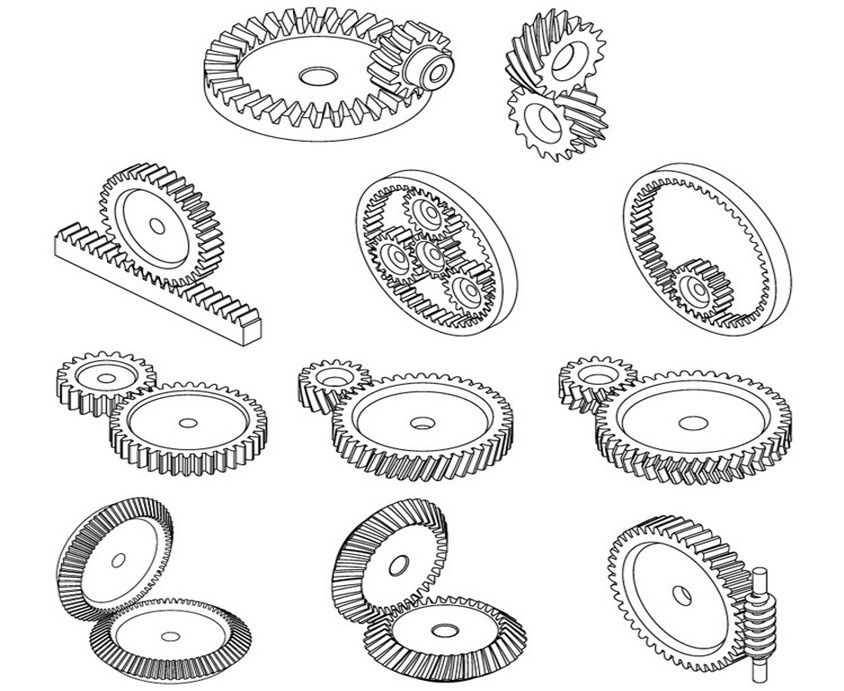

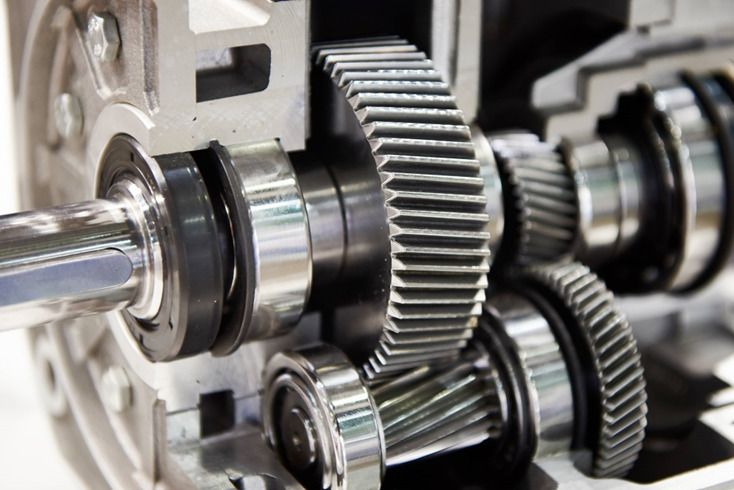

Spur Gears

The most common type of gears employed, spur gears are constructed with straight teeth cut or inserted parallel to the gear’s shaft on a circular (i.e., cylindrical) gear body. In mated pairs, these gears employ the parallel axes configuration to transmit motion and power. Depending on the application, they can be mated with another spur gear, an internal gear (such as in a planetary gear system), or a gear rack (such as in a rack and pinion gear pair).

The simplicity of the spur gear tooth design allows for both a high degree of precision and easier manufacturability. Other characteristics of spur gears include lack of axial load (i.e., the thrust force parallel to the gear shaft), high-speed and high-load handling, and high efficiency rates. Some of the disadvantages of spur gears are the amount of stress experienced by the gear teeth and noise produced during high-speed applications.

This type of gear is used for a wide range of speed ratios in a variety of mechanical applications, such as clocks, pumps, watering systems, power plant machinery, material handling equipment, and clothes washing and drying machines. If necessary for an application, multiple (i.e., more than two) spur gears can be used in a gear train to provide higher gear reduction.

Helical Gears

Similar to spur gears, helical gears typically employ the parallel axes configuration with mated gear pairs, but, if aligned properly, they can also be used to drive non-parallel, non-intersecting shafts. However, unlike spur gears, these gears are constructed with teeth which twist around the cylindrical gear body at an angle to the gear face. Helical gears are produced with right-hand and left-hand angled teeth with each gear pair comprised of a right-hand and left-hand gear of the same helix angle.

The angled design of helical teeth causes them to engage with other gears differently than the straight teeth of spur gears. As properly matched helical gears come in contact with one another, the level of contact between corresponding teeth increases gradually, rather than engaging the entire tooth at once. This gradual engagement allows for less impact loading on the gear teeth and smoother, quieter operation. Helical gears are also capable of greater load capabilities but operate with less efficiency than spur gears. Further disadvantages include the complexity of the helical tooth design, which increases the degree of difficulty in its manufacturing (and, consequently, the cost) and the fact that the single helical gear tooth design produces axial thrust, which necessitates the employment of thrust bearings in any application which uses single helical gears. This latter necessity further increases the total cost of using helical gears.

|

Type of Gear |

Características |

|

Spur |

|

|

Helical |

|

|

Bevel |

|

|

Worm |

|

|

Rack and Pinion |

|

Bevel Gears

Bevel gears are cone-shaped gears with teeth placed along the conical surface. These gears are used to transmit motion and power between intersecting shafts in applications which require changes to the axis of rotation. Typically, bevel gears are employed for shaft configurations placed at 90-degree angles, but configurations with lesser or greater angles are also manageable.

There are several types of bevel gears available differentiated mainly by their tooth design. Some of the more common types of bevel gears include straight, spiral, and hzpt bevel gears.

Straight Bevel Gears

The most commonly used of the bevel gear tooth designs due to its simplicity and, consequently, its ease of manufacturing, straight bevel teeth are designed such that when properly matched straight bevel gears come into contact with one another, their teeth engage together all at once rather than gradually. As is the issue with spur gears, the engagement of straight bevel gear teeth results in high impact, increasing the level of noise produced and amount of stress experienced by the gear teeth, as well as reducing their durability and lifespan.

Spiral Bevel Gears

In spiral bevel gears, the teeth are angled and curved to provide for more gradual tooth engagement and more tooth-to-tooth contact than with a straight bevel gear. This design greatly reduces the vibration and noise produced, especially at high angular velocities (>1,000 rpm). Like helical gears, spiral bevel gears are available with right-hand or left-hand angled teeth. As is also the case with helical gears, these gears are more complex and difficult to manufacture (and, consequently, more expensive), but offer greater tooth strength, smoother operation, and lower levels of noise during operation than straight bevel gears.

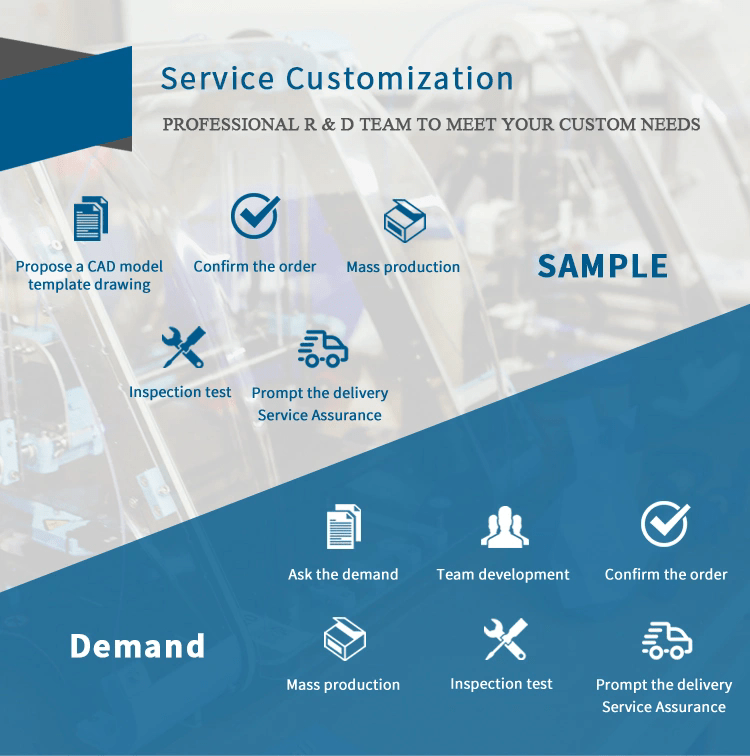

¿Por qué elegirnos?

(1) Proporcionamos servicios OEM y presentamos varios estilos y los últimos diseños a los clientes;

(2) Cooperamos con grandes clientes del Sudeste Asiático, África, Oriente Medio, Norteamérica y Sudamérica;

(3) De acuerdo con las necesidades de los clientes en diferentes regiones, hemos emparejado varios estilos de reductores para usted, ¡para que nuestros clientes tengan una gran competitividad en el mercado!

(4) Contamos con más de 20 años de amplia experiencia en ofrecer a los clientes productos de alta calidad y los servicios más profesionales.

(5) ¡Podemos exportar mercancías de forma flexible desde cualquier puerto de China! ¡Le invitamos a preguntar!

ventaja para la empresa:

1. Gran capacidad de producción y entrega rápida.

2. Estrictas normas de inspección de control de calidad: todos los productos deben pasar la inspección 100% antes de la entrega.

3. Proporcionar servicio OEM/ODM

4. Servicio en línea 24 horas.

5. Consulta de ofertas en tiempo real

6. Alta calidad, gran fiabilidad y larga vida útil del producto.

7. Los fabricantes profesionales ofrecen precios competitivos.

8. Trabajadores cualificados diversificados y con experiencia.

Sistema de gestión de la calidad:

En HZPT, la calidad de los productos y servicios tiene la máxima prioridad.

Nuestros empleados reciben formación sobre métodos y principios de calidad.

En todos los niveles de la organización nos comprometemos a mejorar la calidad de los productos y los procesos.

Un compromiso tan profundo nos ha ayudado a ganarnos la confianza de los clientes y a convertirnos en la marca preferida del mundo.

Paquete y plazo de entrega

Tamaño Dibujos

Caja/contenedor de madera y palet, o según especificaciones personalizadas.

15-25días muestras. 30-45days pedido offcial

Puerto: puerto de Shanghai/Ningbo

Preguntas frecuentes

PREGUNTAS MÁS FRECUENTES:

Al cliente

¿Es rentable comprar en China?

China sigue siendo uno de los mayores proveedores del mundo. Seguro que los productos que ha elegido son rentables en sus mercados objetivo, ya que China suministra al mundo con calidad y precios competitivos.

2) ¿Tengo que viajar a China para comprar productos?

Nos ocupamos de todo por usted, para que pueda ahorrarse los costes de billetes de avión, hoteles y gastos de viaje. Sin embargo, si decide visitar China, intentaremos organizarle una estancia maravillosa para que su experiencia de viaje sea agradable.

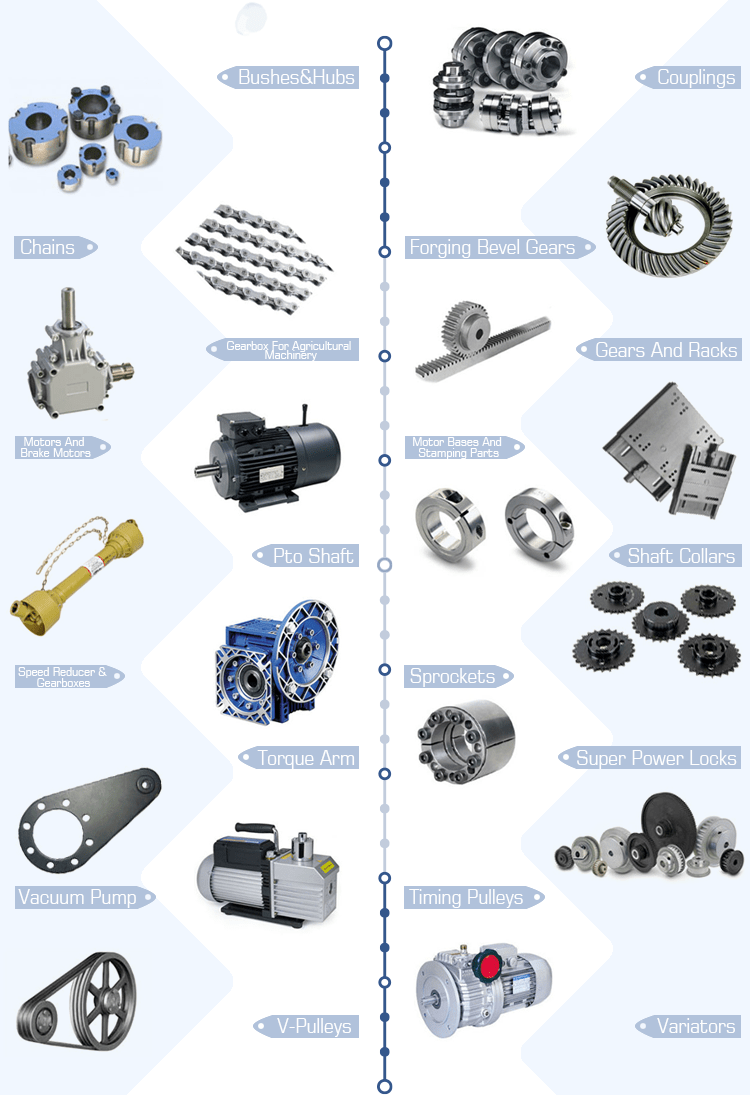

3) ¿Qué tipo de productos suministran?

Una amplia gama de productos industriales, de automoción y agrícolas. Cada producto se asigna a un equipo especializado.

4) ¿Qué riesgos corro comprando en China o trabajando con ustedes?

Básicamente no corre ningún riesgo. Hacemos las compras por usted y puede estar tranquilo con nuestras inspecciones. Si tiene tiempo de venir a China, puede visitarnos durante el proceso de producción. Usted tiene acceso a nuestras redes de contacto y equipo de ventas. Tomaremos medidas serias sobre sus productos como los nuestros. Usted no necesita viajar si usted no quiere como usted tiene socios bien informados en la China.

5) Puedo encontrar el proveedor de mis productos por mi cuenta, ¿para qué os necesito?

Puede hacerlo. Sin embargo, su inversión será mucho mayor. Además, no tienes un socio local que conozca el mercado y pueda darte acceso a una red de oportunidades.

Para comprar sus productos en China, necesita tener una oficina local para firmar contratos con los proveedores, un equipo de ingenieros para realizar inspecciones de calidad y cantidad de vez en cuando. Debe conocer las fuentes de materias primas, y lo más importante es evitar la subcontratación.

6) ¿Cómo está estructurado?

Disponemos de diferentes departamentos especializados en cada uno de los aspectos. Podemos proporcionarle asistencia logística, asistencia en materia de abastecimiento, asistencia en materia de inspección y asistencia jurídica.

7) ¿Este servicio es sólo para grandes empresas?

No, estamos seguros de que por primera vez corporación obtendrá cálida confianza para mantener su negocio con nosotros, como nuestra relación basada en la honestidad y el beneficio mutuo, por lo que en el futuro va a ampliar su negocio. Nos preocupamos por usted y hacer que usted sea mucho más fuerte que antes. Vamos juntos de fuerza en fuerza.

Damos la bienvenida a cualquier corporación de Pequeña a Grande, Progresemos. . .

Para más información, envíenos un correo electrónico

/helica1.jpg)