The accessory gearbox stands as a pivotal component in the mechanical world, seamlessly transferring power within machinery to ensure optimal performance. Predominantly found in the realms of aviation, automotive, and industrial machinery, its role is both crucial and multifaceted. This guide demystifies the accessory gearbox, shedding light on its operation, types, applications, and best practices for selection and maintenance.

Accessory Gearbox Fundamentals

Definition and Function

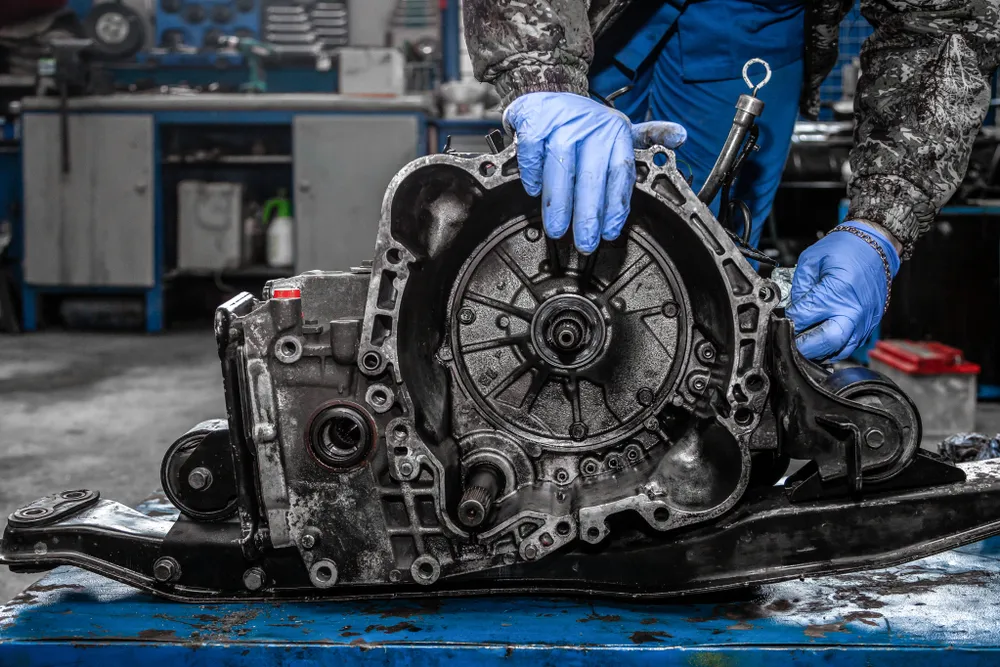

An accessory gearbox (AGB) is a critical mechanical component designed to distribute power from the primary engine or motor to various auxiliary systems and accessories in machinery. It functions by converting the engine's power into the required form and speed for operating these auxiliary components. The accessory gearbox achieves this through a series of gears and shafts that adjust the output speed and torque according to the needs of the connected accessories.

Primary Functions of an Accessory Gearbox:

- Power Distribution: The AGB efficiently allocates power from a single source (such as an aircraft engine, automobile engine, or industrial motor) to multiple auxiliary systems. This distribution is crucial for the simultaneous operation of several components, each with its unique power requirements.

- Speed and Torque Modification: By changing the gear ratios, the accessory gearbox can increase or decrease the speed and torque of the power being transmitted. This is essential because different accessories may require different speeds and torque levels to operate optimally. For example, a hydraulic pump might need a different speed and torque than an alternator, even though both are powered by the same engine.

- Directional Change: In some applications, the AGB also alters the direction of the power transmission. This is particularly relevant in complex machinery where the spatial arrangement of components requires power to be transmitted in various directions.

Key Components of an Accessory Gearbox:

- Gears: The core components of an AGB, gears are responsible for the transmission and modification of power. They come in various types, such as spur, helical, bevel, or worm gears, each offering different advantages in terms of efficiency, noise, and torque capacity.

- Shafts: Shafts transfer rotational power from the engine to the gears and from one gear to another within the gearbox.

- Bearings: Bearings support the rotational shafts, reducing friction and wear, thereby ensuring smooth operation.

- Housings: The gearbox housing contains the gears and shafts, providing protection and structural support. It also acts as a mounting point for the gearbox within the machinery.

Types and Construction

Among the plethora of gearbox types, two stand out for their prevalent use and efficiency: helical gearboxes and worm gearboxes. Helical gearboxes, recognized for their angled teeth, provide smooth and quiet operation, making them ideal for environments where noise reduction is crucial. Worm gearboxes, on the other hand, feature a worm (screw) that meshes with a worm gear (wheel), offering high torque at low speeds and a natural locking mechanism that prevents backdriving, enhancing safety in load-bearing applications.

Applications Across Fields

In Aviation

In aircraft, the accessory gearbox plays a vital role by powering systems crucial for flight, such as fuel pumps, hydraulic pumps, and generators. Its ability to reliably distribute power under the demanding conditions of flight highlights its importance in aviation technology.

In the Automotive Sector

High-performance vehicles benefit from accessory gearboxes by achieving greater efficiency and responsiveness. These gearboxes enhance the transfer of power to essential components like alternators and water pumps, ensuring the vehicle operates at peak efficiency.

Industrial Use

Heavy machinery and industrial setups rely on accessory gearboxes for smooth operation and durability. They ensure that machines can handle the strenuous workloads typical in manufacturing and production industries, translating to increased productivity and reduced downtime.

Choosing the Right Accessory Gearbox

Choosing the right accessory gearbox (AGB) is a crucial decision that can significantly impact the performance and efficiency of your machinery. Whether for aviation, automotive, industrial applications, or other mechanical systems, selecting the most suitable AGB involves several critical considerations. Here's a guide to help you navigate through the selection process:

Understand Your Requirements

- Load Capacity: Determine the maximum load the gearbox will need to handle. This includes understanding the torque requirements of the driven accessories.

- Speed Requirements: Know the input speed from the power source and the required output speed for each accessory. This will help in selecting a gearbox with the appropriate gear ratio.

- Direction of Power Transmission: Consider if you need the gearbox to change the direction of the power flow, which is common in systems where space constraints exist.

Evaluate Gearbox Types

Different types of gearboxes offer varied characteristics. Your application may benefit from one type over another based on efficiency, noise levels, or operational requirements:

- Helical Gearboxes: Known for their quiet operation and high efficiency, suitable for applications where noise is a concern.

- Worm Gearboxes: Provide high torque at low speeds and have a natural braking feature, ideal for heavy-load applications.

- Planetary Gearboxes: Offer high torque density and compact size, perfect for space-constrained applications.

- Spur Gearboxes: Simple and cost-effective, best used in applications where noise is less of a concern.

Consider the Operating Environment

- Environmental Conditions: Gearboxes operating in harsh environments (e.g., high temperatures, corrosive substances) require materials and seals that can withstand these conditions.

- Lubrication and Maintenance: Some gearboxes require more maintenance than others. Consider the ease of maintenance and lubrication needs, especially in remote or difficult-to-access locations.

Assess Power Source Compatibility

Ensure the gearbox is compatible with your power source in terms of input type (electric motor, internal combustion engine) and characteristics (speed, horsepower). This compatibility is crucial for efficient power transmission.

Look for Quality and Reliability

- Manufacturer Reputation: Choose gearboxes from reputable manufacturers known for quality and reliability. This can save costs and prevent downtime in the long run.

- Warranty and Support: A solid warranty and accessible technical support are indicators of a manufacturer's confidence in their product and their commitment to customer service.

Future-proof Your Selection

- Scalability: Consider whether the gearbox can handle future increases in load or changes in operational requirements.

- Modularity: Some gearboxes offer modularity, allowing for easier upgrades or modifications as your system evolves.

Cost Considerations

While it's important to find a cost-effective solution, the cheapest option isn't always the best in terms of total cost of ownership. Evaluate the operational and maintenance costs over the gearbox's expected lifespan.

Consult with Experts

When in doubt, consulting with engineering experts or the gearbox manufacturers can provide valuable insights. They can offer personalized recommendations based on their experience and understanding of your specific requirements.

Selecting the right accessory gearbox is a process that requires careful consideration of your system's needs, environmental conditions, and future requirements. By taking the time to evaluate these factors, you can ensure that your choice will provide the efficiency, reliability, and performance needed for your application.

Maintenance and Troubleshooting

Common Issues and Solutions

Accessory gearboxes may encounter problems such as wear and tear, overheating, and lubrication issues. Regular inspections and adhering to a maintenance schedule can preempt many of these issues, ensuring the gearbox's longevity and reliability.

Maintenance Recommendations

Proactive measures, including regular lubrication, temperature monitoring, and wear assessment, are crucial. Additionally, understanding the symptoms of common issues allows for timely interventions that can prevent more significant problems.

The accessory gearbox is a cornerstone of modern mechanical systems, pivotal in a wide array of applications from the skies to the roads and beyond. Its selection and maintenance are critical to the seamless operation and longevity of machinery. With careful consideration and adherence to best practices, the accessory gearbox can significantly enhance the efficiency and reliability of any mechanical system.