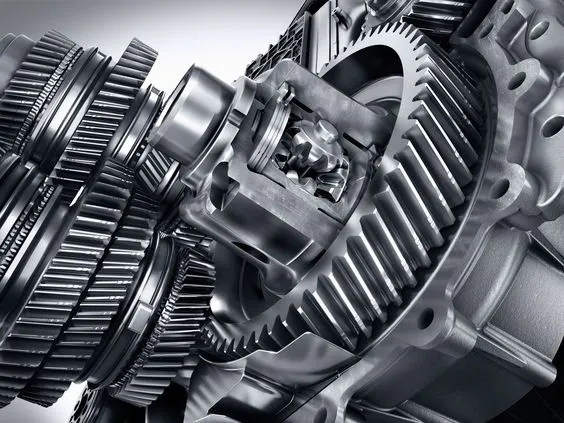

In the intricate world of machinery, the gearbox stands out as a critical component, elegantly managing the transfer of power from the engine to the operational parts of the machine. Central to its function is gearbox oil, a specially formulated lubricant that plays multiple roles—from reducing friction to cooling gears and facilitating smooth transitions between gears. The importance of this oil in prolonging machinery life and enhancing performance cannot be understated. Through this article, we dive deep into the nuances of gearbox oil, exploring its types, the significance of proper selection, and the intricacies of maintenance. Whether you're a machinery enthusiast, a professional mechanic, or simply curious, understanding gearbox oil is essential for anyone keen on machinery maintenance and optimization.

What is Gearbox Oil?

Gearbox oil, also known as transmission fluid, is a specialized lubricant designed for use in the transmission system of vehicles and machinery. The primary function of gearbox oil is to reduce friction between the moving parts within the gearbox, which in turn helps in transmitting power efficiently from the engine to the wheels or machinery parts. Gearbox oil plays several critical roles in the operation of a gearbox, including:

- Lubrication: It forms a protective film over components to minimize direct metal-to-metal contact, reducing wear and extending the life of the gearbox.

- Cooling: By circulating through the gearbox, the oil carries away heat generated by friction and the operation of the gearbox, helping to maintain an optimal operating temperature and preventing overheating.

- Cleaning: Gearbox oil is formulated to help keep the gearbox clean by suspending contaminants and debris within the fluid, which are then removed through the transmission's filtration system.

- Protection: It provides protection against rust and corrosion to the metallic components of the gearbox, which is especially important in harsh operating environments.

- Enhanced Performance: High-quality gearbox oil can significantly improve shifting performance, ensuring smoother gear changes and contributing to a better driving experience.

Types of Gearbox Oil

Gearbox oil, integral for the smooth functioning and longevity of transmission systems, comes in various formulations to meet differing requirements and operating conditions. Here are the primary types of gearbox oil, each with its unique characteristics and applications:

Mineral Gearbox Oil

- Description: Mineral gearbox oils are derived directly from crude oil, undergoing a refining process to achieve the desired lubrication properties. They are the traditional choice for gearbox lubrication.

- Applications: Suited for older vehicles and machinery that don't operate under extreme conditions or high-performance demands. They are often more cost-effective but may require more frequent changes.

- Pros: Cost-effective, widely available.

- Cons: Less thermal stability, more frequent changes required, not ideal for extreme conditions.

Synthetic Gearbox Oil

- Description: Synthetic gearbox oils are chemically engineered lubricants designed to offer superior performance in terms of stability, temperature resistance, and longevity. They provide excellent protection under extreme conditions and over a broader temperature range.

- Applications: Ideal for modern, high-performance vehicles and machinery, as well as equipment operating in extreme environments (very high or low temperatures).

- Pros: Superior thermal stability, longer life, improved fuel efficiency, better performance in extreme conditions.

- Cons: More expensive than mineral oils.

Semi-Synthetic Gearbox Oil

- Description: Semi-synthetic or synthetic blend gearbox oils combine mineral oil with synthetic oil, aiming to offer a balance between performance and cost. They provide better protection and performance than mineral oils but at a lower cost than fully synthetic options.

- Applications: Suitable for a wide range of vehicles and machinery, offering a good compromise for those who want improved performance over mineral oils but without the higher price tag of full synthetics.

- Pros: Better performance than mineral oils at a moderate price, improved thermal stability and longevity.

- Cons: Not as high-performing as full synthetics in extreme conditions.

Specialty Gearbox Oils

- Description: These are gearbox oils formulated with specific additives or properties tailored for particular applications, such as gearboxes with wet clutches, heavy-duty industrial equipment, or vehicles operating in severe conditions.

- Applications: Specific to the equipment's requirements, such as racing cars, motorcycles with wet clutches, heavy construction machinery, or agricultural equipment.

- Pros: Customized protection and performance for specific needs or conditions.

- Cons: May be more expensive and less widely available than more general types.

Automatic Transmission Fluid (ATF)

- Description: Although not traditionally referred to as “gearbox oil,” ATF is a type of transmission fluid specifically designed for use in automatic transmission systems. It has unique properties and additives to handle the automatic gearbox's requirements, such as hydraulic functions, gear lubrication, and cooling.

- Applications: Exclusively used in automatic transmissions and some modern manual transmission vehicles.

- Pros: Formulated for the high demands of automatic transmissions, including lubrication, hydraulic operation, and temperature control.

- Cons: Not suitable for manual transmissions unless specified by the manufacturer.

When selecting gearbox oil, it's crucial to consider the manufacturer's recommendations, the operating environment, and the specific demands of the machinery or vehicle. Using the correct type and grade of oil is essential for optimal performance and to avoid potential damage to the gearbox.

Why Gearbox Oil Matters

Gearbox oil plays a pivotal role in the maintenance and performance of transmission systems, influencing not only the longevity of the gearbox but also the efficiency and reliability of the entire machinery or vehicle. Here are several reasons why gearbox oil matters significantly:

Reduction of Friction and Wear

The primary function of gearbox oil is to lubricate the moving parts within the gearbox. By creating a thin layer between metal surfaces, it significantly reduces friction and prevents direct metal-to-metal contact. This reduction in friction minimizes wear on the gears and bearings, extending their lifespan and ensuring smooth operation.

Cooling

Gearboxes generate a lot of heat due to mechanical friction and the shear stress within the oil. Gearbox oil plays a crucial role in dissipating this heat, carrying it away from the gears and other components to maintain an optimal operating temperature. Overheating can lead to gearbox failure, making the cooling property of gearbox oil critical for preventing such outcomes.

Protection Against Corrosion

Gearbox components are susceptible to rust and corrosion, particularly in harsh environments. Gearbox oil contains additives that protect these metal parts from corrosive substances and moisture that can enter the system. This protective barrier prolongs the life of the gearbox and maintains its efficiency.

Cleaning

Over time, debris such as metal shavings and external contaminants can accumulate in the gearbox. Many gearbox oils are formulated with detergents and dispersants that help keep the gearbox clean by suspending these particles within the oil, which are then removed through the oil filter. This cleaning action prevents sludge buildup and ensures the smooth operation of the gearbox.

Enhanced Performance

The right gearbox oil can significantly improve the overall performance of the machinery or vehicle. It ensures that gear changes are smooth and efficient, reduces energy loss, and improves the responsiveness of the transmission system. For high-performance or heavily loaded systems, specialized gearbox oils can offer additional benefits like improved fuel efficiency and reduced operating costs.

Preventing Leakages and Seal Preservation

Gearbox oil formulations often include seal conditioners that help maintain the flexibility and integrity of seals within the gearbox, preventing leaks. Leaks not only lead to a loss of oil but can also cause contamination of the system and environmental damage.

Compliance with Manufacturer Specifications

Manufacturers design gearboxes with specific types of oil in mind, tailoring the system's components to the properties of the recommended oil. Using the correct gearbox oil is essential for meeting these specifications and ensuring the gearbox operates as intended.

In summary, gearbox oil is fundamental to the health and performance of transmission systems. Regular checks, timely changes, and using the correct type of oil are crucial maintenance steps that can prevent costly repairs and downtime, ensuring the machinery or vehicle operates reliably and efficiently over its lifespan.