Gearbox reconditioning is an essential maintenance task that can significantly extend the life of machinery and vehicles by restoring gearboxes to their optimal operating condition. This guide explores the why, when, and how of gearbox reconditioning, providing practical advice for ensuring your gearbox operates smoothly and efficiently.

Understanding Gearbox Reconditioning

What Is Gearbox Reconditioning?

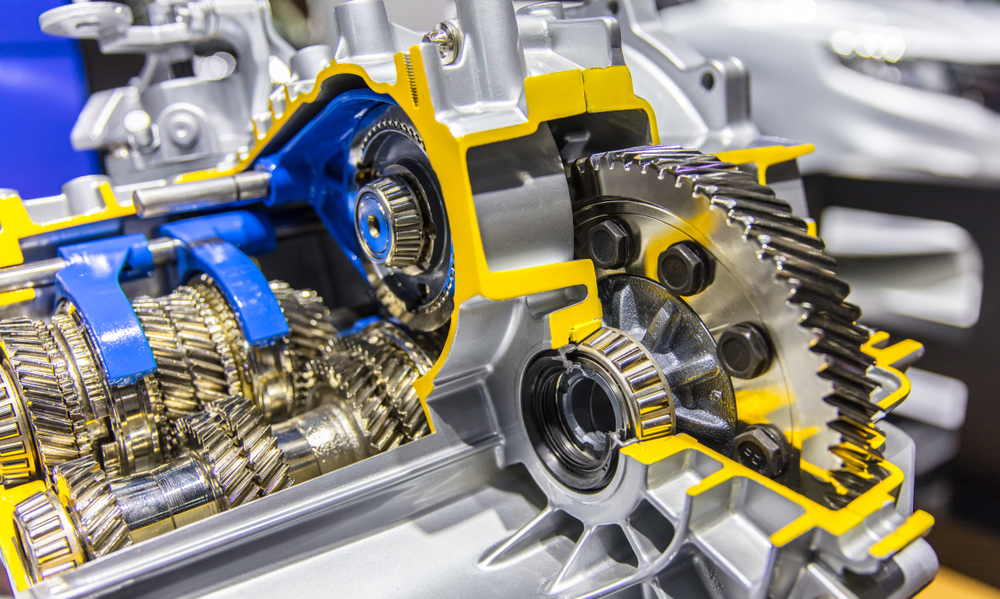

Gearbox reconditioning involves inspecting, cleaning, repairing, or replacing worn or damaged parts of a gearbox. This process can vary from simple maintenance tasks to a complete overhaul, depending on the gearbox's condition.

The Importance of Gearbox Reconditioning

- Extends Gearbox Life: Regular reconditioning can significantly extend a gearbox's operational lifespan, delaying the need for costly replacements.

- Improves Efficiency: A reconditioned gearbox operates more efficiently, with smoother gear changes and reduced energy or fuel consumption.

- Prevents Breakdowns: Identifying and addressing issues early through reconditioning can prevent unexpected and potentially dangerous breakdowns.

When to Consider Gearbox Reconditioning

Considering gearbox reconditioning is pivotal in maintaining the efficiency, longevity, and reliability of machinery across various applications. Knowing when to opt for reconditioning over repairs or replacement can save costs and ensure continuous operation. Here are key indicators and situations when gearbox reconditioning becomes necessary:

Excessive Noise or Vibration

- Unusual Sounds: Grinding, whining, or knocking sounds from the gearbox often indicate internal wear, such as damaged gears or bearings. These sounds are usually the first sign that the gearbox may need attention.

- Increased Vibration: While some vibration is normal, a noticeable increase can signify misalignment, imbalance, or wear within the gearbox. Persistent vibration can lead to further damage if not addressed.

Performance Degradation

- Reduced Efficiency: A drop in performance, such as the machinery running slower than usual or requiring more power to perform the same tasks, could indicate that the gearbox is not operating optimally.

- Difficulty in Shifting Gears: For gearboxes with multiple gears, difficulty or reluctance in shifting can be a sign of worn components or misalignment within the gearbox.

Oil Leaks and Contamination

- Visible Leaks: Oil leaks around the gearbox seals or gaskets are clear indicators that components may be worn and require replacement.

- Oil Condition: If the oil becomes contaminated with metal particles, it's a sign of internal wear. The presence of excessive debris or a burnt smell in the oil can also indicate overheating or component degradation.

Routine Maintenance and Inspection Findings

- Wear and Tear: Regular maintenance checks might reveal wear on gears and bearings that could lead to failure if not addressed. Reconditioning at this stage can prevent unexpected breakdowns.

- Service Life: Gearboxes have an expected service life under normal operating conditions. As a gearbox approaches or exceeds this lifespan, reconditioning can rejuvenate it, extending its operational life.

After a Significant Operation Period

- Long-Term Use: Even without obvious signs of failure, gearboxes benefit from reconditioning after long periods of continuous use. This preventive measure can refresh the system, replacing any components that might fail soon.

Changes in Operational Demands

- Increased Load Requirements: If the operational demands on the gearbox increase, reconditioning can ensure that it meets the new requirements by upgrading components to handle higher loads or speeds.

Cost-Benefit Analysis

- Cost-Effective Solution: In many cases, reconditioning a gearbox is more cost-effective than complete replacement, especially for high-value or custom gearboxes. It can restore functionality and efficiency at a fraction of the cost of buying a new gearbox.

Sustainability Considerations

- Environmental Impact: Reconditioning a gearbox, rather than replacing it, reduces waste and the need for new materials. This approach aligns with sustainability goals by extending the life of existing components.

Deciding to recondition a gearbox involves assessing these factors and considering the implications of downtime, costs, and operational requirements. It's often beneficial to consult with a professional service provider who can offer an expert assessment of the gearbox's condition and recommend the best course of action. Reconditioning not only restores gearbox performance but also represents a responsible choice for equipment management and environmental stewardship.

The Gearbox Reconditioning Process

A step-by-step overview of the reconditioning process helps demystify what happens during a gearbox service.

Inspection and Diagnosis

- Visual Inspection: Checking for external signs of wear, oil leaks, or damage.

- Diagnostic Tests: Using specialized tools to identify any internal issues.

Disassembly and Cleaning

- Component Disassembly: Carefully taking apart the gearbox to access all internal components.

- Cleaning: Removing debris, grime, and old lubricant from each part.

Repair and Replacement

- Assessment of Wear: Evaluating the condition of gears, bearings, seals, and other components.

- Part Replacement: Replacing worn or damaged parts with new or refurbished components.

Reassembly and Testing

- Careful Reassembly: Putting the gearbox back together according to manufacturer specifications.

- Performance Testing: Running the gearbox through tests to ensure it operates correctly and efficiently.

Choosing a Gearbox Reconditioning Service

Selecting the right service provider is crucial for a successful gearbox reconditioning. Consider factors like experience, reputation, and the use of quality parts. Seeking recommendations and reading reviews can also guide your choice.

Maintenance Tips to Reduce the Need for Gearbox Reconditioning

Maintaining a gearbox in optimal condition is essential for ensuring the longevity and efficiency of machinery in various industries. Regular and proactive maintenance can significantly reduce the need for frequent reconditioning. Here are key maintenance tips designed to minimize wear and tear, ultimately reducing the likelihood of extensive gearbox repairs or replacements.

Regular Lubrication

- Choose the Right Lubricant: Always use the lubricant specified by the gearbox manufacturer. Different gearboxes may require specific types of lubricants based on their design and operational requirements.

- Lubrication Schedule: Adhere to the manufacturer's recommended lubrication schedule. Regular lubrication reduces friction between moving parts, minimizing wear.

- Monitor Lubricant Condition: Check the lubricant regularly for signs of contamination or degradation. Contaminants like water or debris can significantly impact the lubricant's effectiveness and damage gearbox components.

Routine Inspections

- Visual Inspections: Regularly inspect the gearbox for signs of wear, leaks, or damage. Catching issues early can prevent them from escalating into more significant problems.

- Listen for Abnormal Noises: Unusual sounds like grinding or whining can indicate issues within the gearbox, such as bearing failure or gear damage. Identifying and addressing these sounds early can prevent more extensive damage.

- Vibration Analysis: Periodically, use vibration analysis tools to detect abnormalities in the gearbox operation that might not be visible or audible. Excessive vibration can indicate misalignment, imbalance, or wear.

Keep Gearbox Clean

- External Cleaning: Keep the gearbox exterior clean to prevent overheating and to allow for easier inspection. Dust and debris can act as insulators, which increase operating temperatures, or can become contaminants if they enter the gearbox.

- Prevent Contamination: Ensure that the gearbox is sealed properly to prevent contaminants from entering, especially in environments with high levels of dust or moisture.

Temperature Monitoring

- Monitor Operating Temperatures: Excessive heat can be a sign of internal issues, such as overloading or lubrication failure. Use temperature monitoring devices to ensure the gearbox operates within safe temperature ranges.

Seal and Gasket Maintenance

- Inspect Seals Regularly: Check seals and gaskets for any signs of wear or leaks. Even minor leaks can lead to significant lubricant loss and contamination, affecting the gearbox's performance and lifespan.

- Replace as Needed: Replace worn or damaged seals promptly to maintain the integrity of the gearbox and prevent contaminants from entering.

Correct Installation and Alignment

- Ensure Proper Installation: Incorrect installation can lead to misalignment, which puts additional stress on the gearbox and can cause premature wear or failure.

- Alignment Checks: Regularly check and correct alignment between the gearbox and the driven machinery. Misalignment can result in uneven load distribution and increased wear.

Load Management

- Avoid Overloading: Operating the gearbox beyond its rated capacity can accelerate wear and lead to overheating. Ensure that the load is within the gearbox's specifications.

- Smooth Operation: Avoid sudden starts and stops, which can place additional stress on the gearbox components. Smooth operation helps in prolonging the life of the gearbox.

Professional Maintenance

- Scheduled Professional Inspections: Even with diligent in-house maintenance, having the gearbox inspected by a professional can help identify potential issues that may not be apparent to onsite personnel. Professionals can also perform detailed analysis and adjustments to optimize performance.

Following these maintenance tips can significantly reduce the frequency and necessity for gearbox reconditioning. A well-maintained gearbox not only operates more efficiently but also enjoys a longer service life, contributing to the overall productivity and cost-effectiveness of the machinery it powers.

Conclusion

Gearbox reconditioning is a vital aspect of maintaining the performance and longevity of any machinery or vehicle. Understanding the signs that reconditioning is needed, the process involved, and how to choose a service provider will help ensure your gearbox continues to function efficiently and reliably.