In the industrial landscape, gearboxes stand as the backbone of machinery, orchestrating the seamless transmission of power from engines to operational components. Integral to their performance is the gearbox oil, which demands meticulous monitoring and maintenance. This guide embarks on an in-depth exploration of how to check the oil level in industrial gearboxes, a pivotal routine maintenance task that safeguards machinery health and operational efficiency.

Deep Dive into Industrial Gearboxes

Understanding Gearboxes

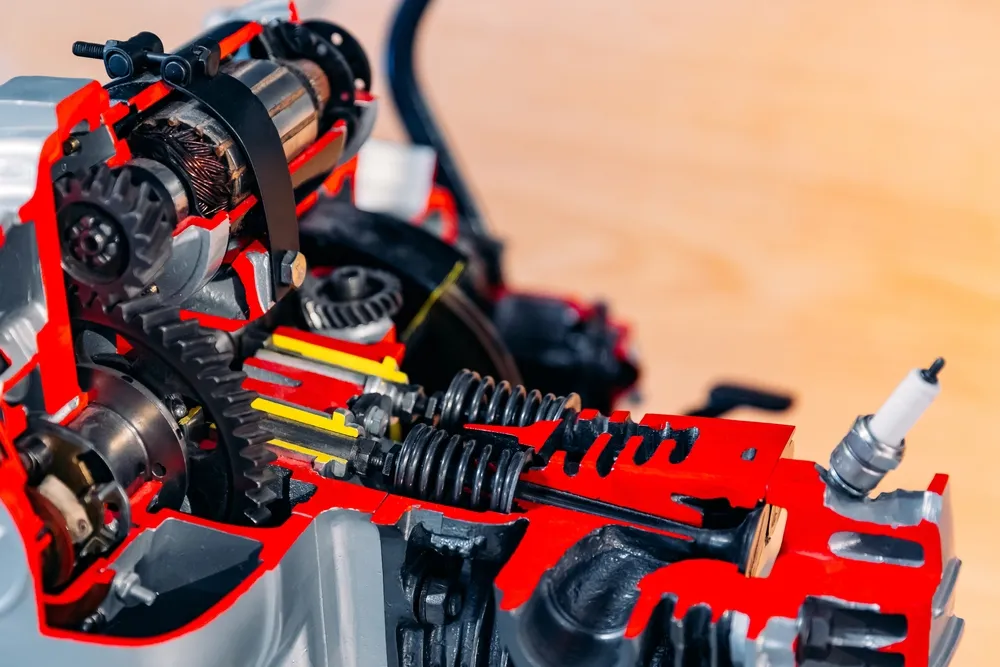

At their core, industrial gearboxes are complex assemblies that adjust the torque and speed transmitted from a power source to a device. They are categorized into various types, such as helical, bevel, worm, and planetary, each tailored to specific industrial needs. These gearboxes ensure machinery operates at optimal performance levels, making their maintenance a top priority for industrial operations.

The Vital Role of Gearbox Oil

Gearbox oil is more than a lubricant; it's a crucial component that plays multiple roles:

- Lubrication: It reduces friction between moving parts, minimizing wear and extending the gearbox's lifespan.

- Cooling: By absorbing and dissipating heat generated during operation, it prevents overheating.

- Protection: It forms a barrier against corrosion and debris accumulation, shielding internal components.

Neglecting the oil level can lead to dire consequences, including increased wear, overheating, and eventual machinery failure, underscoring the importance of regular checks.

Pre-Check Preparations

Tools and Materials

Prepare the following essentials:

- An oil level gauge or dipstick

- Protective gloves and safety glasses

- Cleaning rags

- A flashlight for enhanced visibility

Safety First

Prioritize safety by wearing the necessary personal protective equipment and adhering to lockout/tagout procedures to disable the machinery, ensuring a secure environment for maintenance tasks.

Checking the Oil Level: A Step-by-Step Guide

Step 1: Gearbox Access

Locate the gearbox's oil level indicator. It's typically found on the gearbox housing, either as a dipstick, a sight glass, or an inspection port. Clean the area meticulously to prevent any contaminants from entering during the inspection.

Step 2: The Inspection

For dipstick-equipped gearboxes:

- Withdraw the dipstick, wiping it clean.

- Reinsert it fully, then remove to check the oil mark, ensuring it falls between the minimum and maximum indicators.

For sight glass models:

- Clear any dirt from the sight glass.

- Observe the oil level, which should ideally sit at the midpoint of the sight glass.

Step 3: Interpreting the Findings

A low oil level signals potential leaks or excessive consumption, warranting immediate replenishment and further investigation. Conversely, an excessively high level may indicate overfilling, posing risks of pressure build-up and necessitating oil drainage to optimal levels.

Addressing Common Challenges

Tackling Low Oil Levels

Investigate for leaks around seals and gaskets, addressing any findings promptly. Continuous oil top-ups without fixing leaks can lead to significant machinery wear and operational inefficiencies.

Managing High Oil Levels

Consistently high oil levels can strain seals and lead to leaks. Ensure adherence to manufacturer-recommended oil volumes, adjusting as necessary by draining excess oil.

Dealing with Contaminated Oil

Contamination—signaled by a milky appearance or a burnt odor—compromises gearbox efficiency and requires oil replacement. Investigate the contamination source to prevent recurrence.

Beyond Oil Level Checks

Regular Maintenance Insights

Adopt a comprehensive maintenance routine, including regular oil level checks, periodic oil changes based on manufacturer recommendations or analysis, and maintenance log upkeep to monitor gearbox health.

Selecting the Right Oil

The choice of oil is paramount. Consider the gearbox type, operational conditions, and manufacturer guidelines to select an oil that ensures peak gearbox performance.

Longevity and Gearbox Health

Incorporate additional maintenance practices, such as inspecting seals for leaks and monitoring gearbox temperatures, to preempt issues and extend gearbox life.

Regularly checking the oil level in industrial gearboxes is a fundamental yet crucial maintenance task, pivotal for the seamless operation and longevity of machinery. This guide has navigated through the essential steps and considerations, aiming to equip maintenance professionals with the knowledge to perform this task efficiently and safely. Embracing these practices will not only enhance machinery reliability but also contribute significantly to operational excellence.

Long-Term Gearbox Maintenance Strategies

Ensuring the long-term health of your industrial gearbox goes beyond just checking the oil level. Here are some strategies:

- Regular Oil Analysis: Periodically send oil samples for laboratory analysis to check for contaminants and wear particles. This can help predict potential failures before they occur.

- Vibration Analysis: Implementing regular vibration analysis can detect issues like misalignment, imbalance, or bearing failures early.

- Temperature Monitoring: Continuous monitoring of gearbox temperature can indicate lubrication issues or excessive load, allowing for preemptive maintenance actions.

- Scheduled Maintenance: Beyond oil checks, ensure a comprehensive maintenance schedule that includes inspecting and replacing worn parts, checking seals for integrity, and ensuring all fasteners are tightened to the correct torque specifications.

Advanced Tips for Gearbox Maintenance

- Use Synthetic Lubricants: Consider using synthetic lubricants for better performance in extreme temperatures and extended lubrication intervals.

- Implement Remote Monitoring: Leverage IoT devices for real-time monitoring of gearbox parameters like temperature, vibration, and oil quality. This can significantly enhance predictive maintenance efforts.

- Educate Maintenance Staff: Regular training sessions for maintenance personnel on the latest gearbox maintenance practices can greatly improve the reliability and efficiency of machinery.

FAQs

Q: How often should I change the gearbox oil? A: The frequency depends on the manufacturer's recommendations, the type of oil used, and the operational conditions. Typically, a change every 12 to 18 months is standard, but always refer to the gearbox manual and oil analysis results.

Q: Can I use any oil for my gearbox? A: No. It's crucial to use the type of oil recommended by the gearbox manufacturer. Using the wrong oil can lead to reduced efficiency, increased wear, or even failure.

Q: What are the signs of gearbox oil needing replacement? A: Indicators include oil discoloration, presence of metal particles or debris, a burnt smell, or a change in viscosity. Regular oil analysis is the best way to determine the oil condition.

Q: How do I know if my gearbox is leaking oil? A: Signs of a leak include oil residue around seals, gaskets, or the gearbox housing. Regular inspections can help identify leaks early.

Q: What should I do if I find metal particles in the gearbox oil? A: Metal particles can indicate internal wear. Stop using the gearbox immediately and inspect it for damaged components. Consider consulting with a gearbox specialist to determine the cause and extent of the damage.

Maintaining the correct oil level in an industrial gearbox is crucial for operational efficiency and machinery longevity. By following the detailed steps outlined for checking the oil level and incorporating the long-term maintenance strategies and tips provided, you can ensure your gearboxes run smoothly and reliably. Remember, proactive maintenance is key to preventing downtime and costly repairs, making it essential to integrate these practices into your regular maintenance schedule.