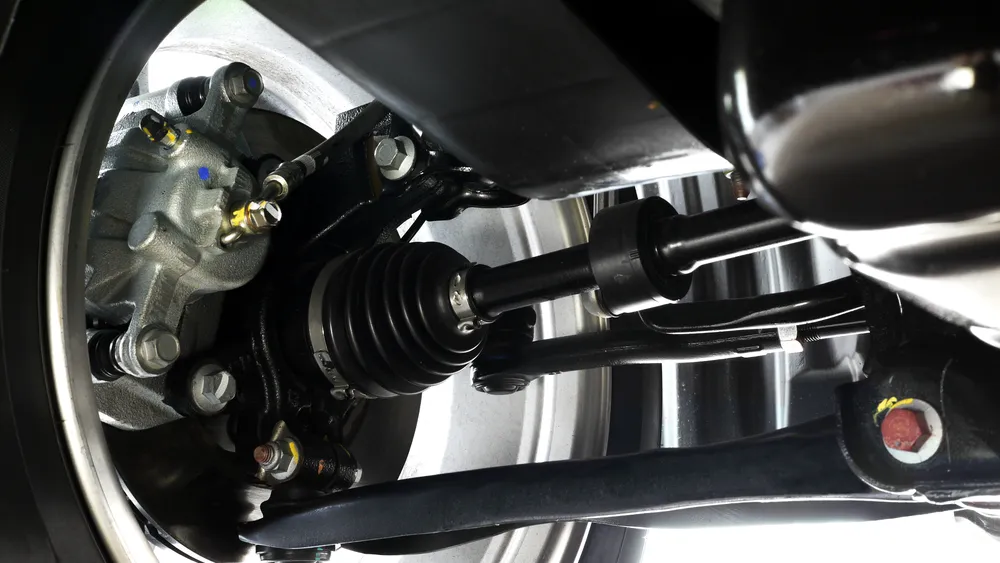

Q: What are the signs of a failing drive shaft? A: Symptoms of a failing drive shaft include vibrations under the vehicle, unusual noises (clunks or squeaks) when accelerating or decelerating, and visible wear or damage to the U-joints. In severe cases, a failing drive shaft can lead to a loss of power transmission from the gearbox to the wheels, significantly affecting the vehicle's drivability.Q: How do I know if the drive shaft or U-joints need replacement? A: Inspect the drive shaft and U-joints for any signs of wear, rust, or damage. Common indicators include excessive play in the U-joints, visible cracks or rust, and stiffness or binding when rotating the drive shaft by hand. If any of these conditions are present, replacement of the affected parts is recommended to maintain proper function and safety of the vehicle.

Q: Can drive shaft removal affect vehicle alignment? A: Removing the drive shaft should not affect the vehicle's wheel alignment since it's part of the drivetrain, not the suspension or steering components. However, if suspension components are disturbed or removed during the process, it's a good idea to check and adjust the alignment to ensure optimal handling and tire wear.

Q: What preventive measures can be taken to avoid drive shaft problems? A: Regular inspection and maintenance are key to preventing drive shaft issues. This includes checking for and addressing signs of wear or damage to the drive shaft and U-joints, ensuring all fasteners are properly torqued, and replacing worn seals to prevent lubricant leaks. Additionally, avoid harsh driving conditions when possible, as excessive strain from activities like off-roading or aggressive acceleration can accelerate wear on these components.

Final Thoughts

Removing and servicing a drive shaft is critical for anyone looking to perform comprehensive maintenance or repairs on their vehicle. While the task may appear challenging at first glance, a methodical approach and a clear understanding of the vehicle's drivetrain can make the process manageable and rewarding. Always prioritize safety, from adequately securing the vehicle before beginning work to wearing the appropriate personal protective equipment. By following the guidelines and tips provided in this guide, you'll be well-equipped to handle drive shaft removal and installation, ensuring your vehicle remains reliable and performs at its best. Remember, the key to success lies in preparation, attention to detail, and a willingness to learn and apply new skills. Whether you're a seasoned professional or a dedicated DIY enthusiast, the ability to service and maintain your vehicle's drivetrain is an invaluable part of automotive care and ownership.