Strength. Reliability. Flexibility.

Motor Gearbox

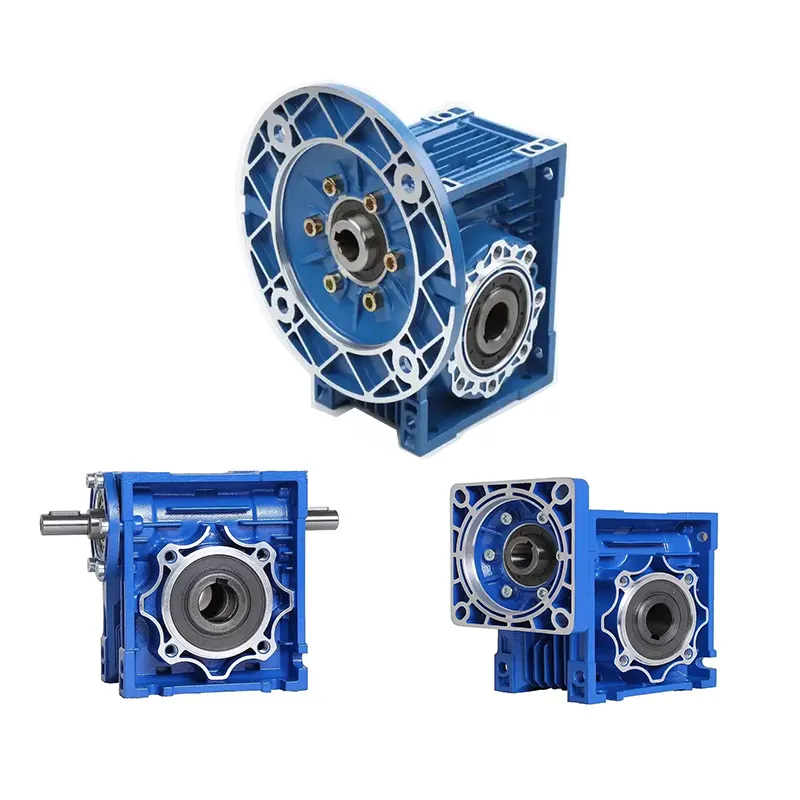

HZPT is a manufacturer and exporter specializing in the design, development and production of motor gearbox. The company has complete machining centers, lathes, gear shaping machines, gear milling machines, gear grinding machines and assembly production lines. And has passed ISO9001:2015 quality management system certification, CE certification, ISO18000 occupational health and safety system certification, ISO14001 environmental management system certification. Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee complete customer satisfaction.

Basics of Motor Gearboxes

A motor gearbox is essentially a specialized component designed to modify the performance characteristics of a motor. By definition, a motor gearbox comprises a series of interconnected gears housed within a durable casing, often referred to simply as a “gearbox” because it is literally a box containing gears. The primary role of this device is to adjust the speed and torque between a motor and the load it drives, which makes it a crucial element in various mechanical systems.

In simpler terms, think of a motor gearbox like the transmission in a car. It takes the speed generated by the engine (or motor, in this case) and adjusts it to something more usable, often increasing the force (torque) at the expense of speed. This trade-off is essential for machinery and devices that need a lot of power but not necessarily high speed, such as industrial equipment and conveyors.

The gears inside a motor gearbox can vary in type, including bevel gears, spiral bevel gears, worm gears, and planetary gears. These gears are mounted on shafts, which are supported by bearings that allow them to rotate smoothly. The entire setup is engineered to efficiently transfer energy from one part of a machine to another, typically to increase torque while simultaneously reducing the output speed of the motor.

Furthermore, the motor gearbox is integral to managing the mechanical energy in a way that suits specific operational needs, such as quieter operation in household appliances or more substantial power in industrial machinery. Over time, like any mechanical component, a motor gearbox can wear out, especially under heavy use. Signs of wear may include unusual noises like whining or screeching, a reduction in efficiency, or even a complete halt in operation. These symptoms suggest that it might be time to replace the motor gearbox to maintain the system’s performance and reliability.

In summary, a motor gearbox is a vital component that adjusts the speed and torque of a motor to meet specific requirements, housed in a robust casing that contains an assembly of various types of gears. Understanding how a motor gearbox functions and recognizing when it might need maintenance or replacement is key to ensuring the longevity and effectiveness of machinery that relies on these powerful devices.

Helical Gearbox

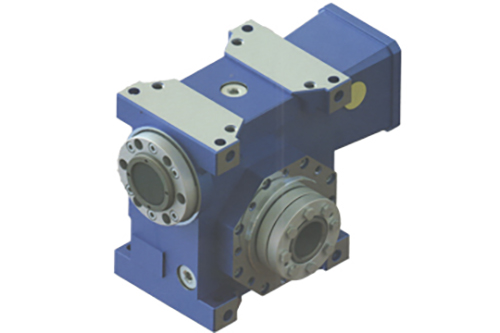

Bevel Gearbox

Spur Gearbox

Showing 1–30 of 437 results

-

Low backlash right angle servo worm gearheads

-

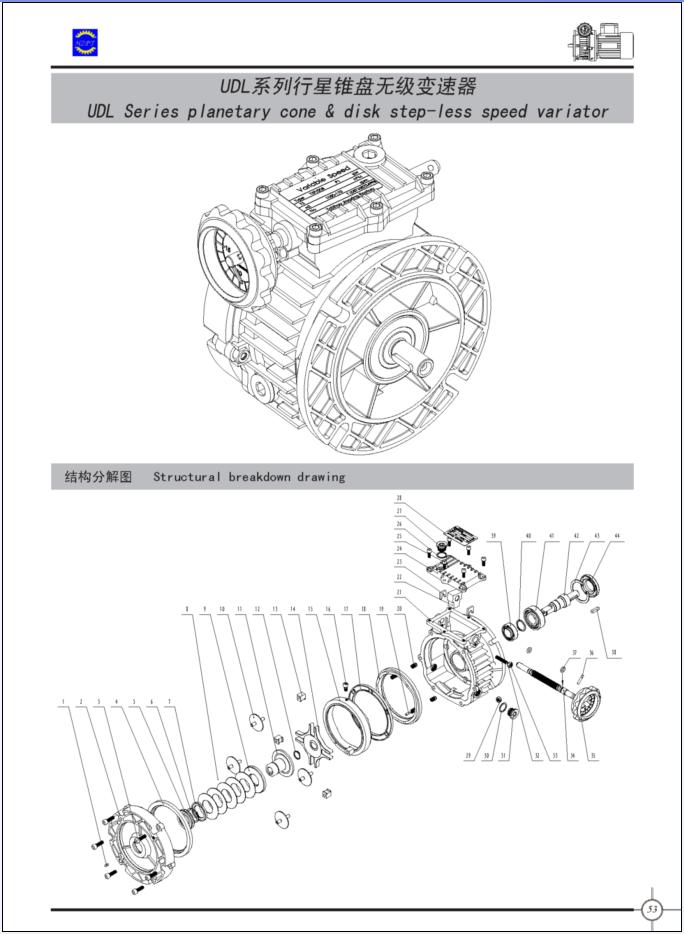

UDL speed variators

-

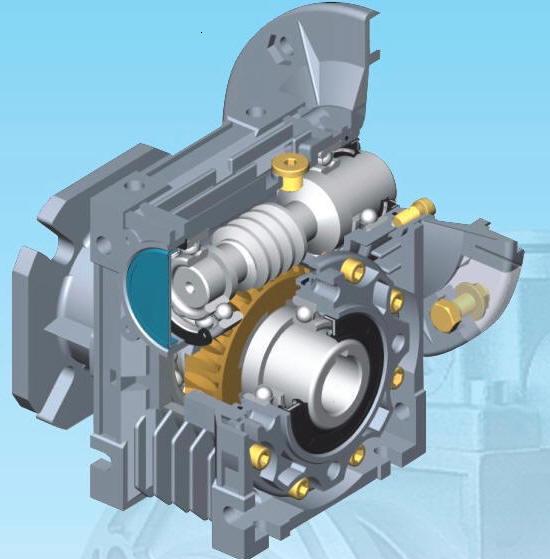

Worm speed reducers

-

WJ SERIES WORM REDUCER

-

Special worm reducers for Greenhouse

-

Worm reducers Inch Dimension Series UY

-

Worm reducers Inch Dimension Wpa

-

Worm reducers Inch Dimension wps

-

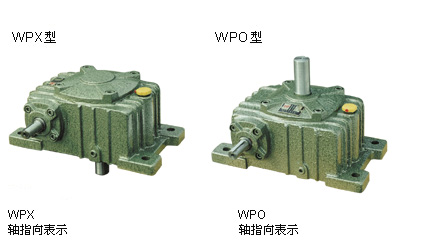

Worm reducers Inch Dimension wpx

-

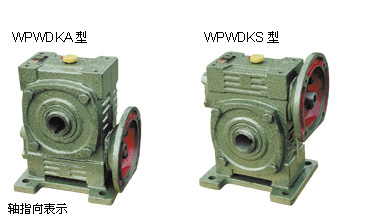

Worm reducers Inch Dimension WPDA

-

Worm reducers Inch Dimension WPDS

-

Worm reducers Inch Dimension WPDX

-

Unipolar turbine reducer Wpw

-

Unipolar turbine reducer Wpws

-

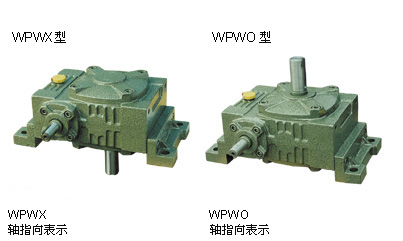

Unipolar turbine reducer Wpwx

-

Unipolar turbine reducer Wpwa

-

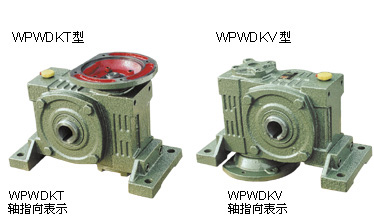

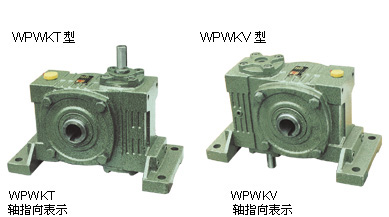

Unipolar turbine reducer WPWDKV

-

Unipolar turbine reducer WPWDKO

-

Unipolar turbine reducer WPWDKS

-

Unipolar turbine reducer WPWDK

-

Unipolar turbine reducer WPWKT

-

Unipolar turbine reducer WPWKO

-

Unipolar turbine reducer WPWK

-

Unipolar turbine reducer WPWDT

-

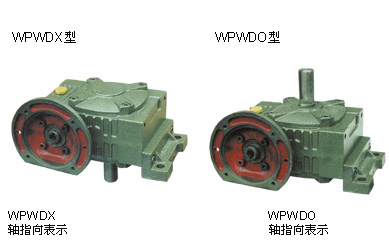

Unipolar turbine reducer WPWDX

-

Unipolar turbine reducer WPWD

-

Unipolar turbine reducer WPWT

-

Unipolar turbine reducer WPWO

-

Unipolar turbine reducer FO

-

Unipolar turbine reducer FA