In the world of mechanical engineering and machinery, every component plays a crucial role in ensuring the efficient and smooth operation of systems. Among these components, gear reducers are fundamental, serving to adjust the speed and torque of motors to the required levels. Within this broad category, the reaction arm kit gear reducer stands out for its specialized function and design. This article delves into what a reaction arm kit gear reducer is, its significance, applications, benefits, and essential considerations for users.

Understanding Gear Reducers

Understanding gear reducers is fundamental to grasping the mechanics behind a wide range of machinery used across industries. Gear reducers are crucial components that modify the speed and torque of a motor to suit the needs of a specific application. This article aims to demystify gear reducers, explaining their purpose, types, applications, and benefits in an easily understandable language.

What Are Gear Reducers?

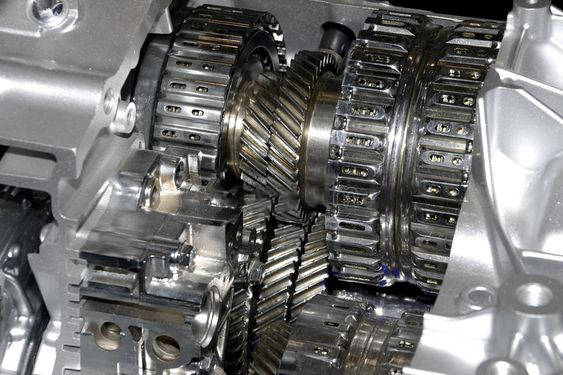

A gear reducer, also known as a gearbox or speed reducer, is a mechanical device that reduces the speed of an input power source, such as an electric motor, while increasing its torque. It consists of a series of gears arranged in such a manner that the output speed is decreased, thereby amplifying the force applied to the machinery.

How Do Gear Reducers Work?

The basic principle behind a gear reducer is the gear ratio, which is the ratio between the rates of the driving gear (input gear) to the driven gear (output gear). When power is transmitted through these gears, the speed produced by the motor is reduced, and in turn, the output torque is increased. The extent of this reduction and increase is determined by the gear ratio.

Types of Gear Reducers

Gear reducers are categorized based on their design and the arrangement of gears. The main types include:

- Spur Gear Reducers: Utilize straight-cut gears and are suitable for low-speed, low-impact applications due to their simple design.

- Helical Gear Reducers: Feature angled teeth, leading to a smoother and quieter operation compared to spur gears, ideal for high-speed applications.

- Worm Gear Reducers: Comprise a worm (screw) and a worm wheel (gear), offering high reduction ratios and a compact design perfect for space-constrained applications.

- Planetary Gear Reducers: Consist of a central sun gear surrounded by planet gears. This design provides high torque density and efficiency, suitable for high-torque applications.

Applications of Gear Reducers

Gear reducers are employed in various applications, necessitating precise control over speed and torque. Some common applications include:

- Conveyor Systems: To control the speed of conveyor belts in manufacturing facilities.

- Automotive Systems: In gearboxes to adjust the speed and torque of the vehicle.

- Robotic Arms: To provide precise movements and handling.

- Aerospace: In actuators and control systems requiring precise torque control.

Benefits of Using Gear Reducers

The use of gear reducers offers several advantages:

- Increased Torque: Allows machinery to handle heavier loads with less input power.

- Controlled Speed: Precisely controls the speed of machinery, essential for tasks requiring delicate handling or precision.

- Enhanced Efficiency: Reduces energy consumption by optimizing the performance of the motor according to the needs of the application.

- Durability and Reliability: Gear reducers are built to withstand harsh conditions, offering a long service life with minimal maintenance.

Gear reducers play an indispensable role in modern machinery, enabling precise control over speed and torque to meet various industrial requirements. Understanding the different types of gear reducers, their working principles, applications, and benefits can help in selecting the right gear reducer for specific needs, ensuring the efficiency and reliability of mechanical systems. Whether it's in a small workshop or a large industrial plant, gear reducers are key to achieving optimal performance in a wide array of mechanical applications.

The Role of Reaction Arm Kit Gear Reducer

mechanical engineering and machinery operation. This device is a sophisticated form of gear reducer that not only modifies the speed and torque of a motor but also ensures precise control and stability during its operation. Understanding its functionality, applications, and benefits is essential for leveraging its capabilities effectively in various industrial applications.

What is a Reaction Arm Kit Gear Reducer?

A reaction arm kit gear reducer is a component used in conjunction with gear reducers to manage and apply torque more accurately and efficiently. It typically consists of a gear reducer fitted with a reaction arm, a mechanical arm designed to absorb and counteract the force generated by the gear reducer. This setup prevents the gear reducer from rotating or moving undesirably due to the torque it produces, ensuring that the output is stable and controlled.

How It Works

The operation of a reaction arm kit gear reducer involves several key steps:

- Torque Generation: The gear reducer receives input from a motor, reducing its speed and increasing its torque.

- Torque Transmission: The increased torque is transmitted to the machinery or application intended for use.

- Force Counteraction: The reaction arm absorbs the reactionary force generated by the torque, preventing the gear reducer from moving or rotating against its mounting point.

- Stabilized Output: The reaction arm ensures that the output torque is delivered smoothly and consistently, without any unintended movements or instability.

Applications

The precision and stability provided by reaction arm kit gear reducers make them suitable for various applications, especially where precise torque control is essential. Some of the common applications include:

- Automated Machinery: In robotic arms and automated production lines where precise movements are crucial.

- Heavy Machinery: In construction and mining equipment where stability and control over high torque outputs are necessary.

- Aerospace and Defense: In actuators and control systems where precise torque application is critical for safety and performance.

- Automotive Industry: In assembly lines and testing rigs, ensuring consistent application of torque in production and maintenance.

Benefits

The use of reaction arm kit gear reducers brings several advantages:

- Enhanced Precision: They allow for precise control over the torque applied, crucial for applications requiring delicate handling or specific torque settings.

- Increased Stability: By counteracting the force generated by the gear reducer, they ensure stable and smooth operation, reducing wear and tear on machinery.

- Improved Safety: The added stability and control help prevent accidents and damage to machinery, especially in high-torque applications.

- Versatility: Suitable for a wide range of industrial applications, from delicate assembly tasks to heavy-duty operations, enhancing their efficiency and reliability.

Key Considerations

When integrating a reaction arm kit gear reducer into a system, several factors must be considered to ensure optimal performance:

- Compatibility: Ensure the gear reducer and reaction arm kit are compatible with the motor and the machinery they are intended to control.

- Mounting Requirements: Proper mounting is essential to leverage the stability offered by the reaction arm, requiring careful planning and execution.

- Maintenance: Regular maintenance is vital to keep the gear reducer and reaction arm in good working condition, ensuring longevity and reliability.

The role of a reaction arm kit gear reducer in modern machinery cannot be overstated. Its ability to provide precise torque control and enhanced stability makes it a valuable component across a wide range of industrial applications. By understanding its operation, applications, and benefits, engineers and technicians can better leverage this technology to improve the efficiency, safety, and reliability of their machinery and processes.

such as robotic arms, conveyor belts, and any machinery requiring specific torque levels to function correctly.

Benefits of Using Reaction Arm Kit Gear Reducers

The use of reaction arm kit gear reducers brings a significant array of benefits across various industries, from manufacturing and automotive to aerospace and robotics. These specialized components are designed to enhance the precision, efficiency, and safety of gear reducer systems. By providing a detailed counterbalance to the torque output, reaction arm kits ensure that the operation of machinery is both smooth and controlled. Here are some key benefits of using reaction arm kit gear reducers:

Enhanced Precision and Control

Reaction arm kit gear reducers allow for highly precise control over the torque output, ensuring that machinery operates within the desired parameters. This precision is crucial in applications requiring meticulous movement and torque application, such as robotic assembly lines or precision machining equipment. By stabilizing the output, these systems can achieve superior accuracy, reducing errors and improving overall product quality.

Increased Stability and Reduced Vibration

The reaction arm serves to counteract the forces that could cause the gear reducer to move or rotate unexpectedly. This counterbalance significantly increases the stability of the entire system, reducing vibrations and minimizing wear and tear on the components. The result is a smoother operation, extended equipment life, and lower maintenance costs.

Improved Safety

By ensuring that the gear reducer operates within its intended parameters and by stabilizing the system against unexpected movements, reaction arm kit gear reducers contribute to a safer working environment. They help prevent accidents that could occur due to equipment malfunction or failure, protecting both the operators and the machinery itself.

Versatility Across Applications

Reaction arm kit gear reducers are versatile components that can be utilized in a wide range of industrial applications. Whether it's for heavy-duty construction equipment, precision aerospace components, automotive assembly lines, or robotic systems, these gear reducers can be tailored to meet the specific needs of each application, enhancing their utility and value.

Enhanced Durability and Reliability

The stability provided by reaction arm kits not only improves performance but also enhances the durability and reliability of the gear reducer and the machinery it powers. By reducing the stress on components and minimizing vibrations, these systems can withstand harsh operating conditions and prolonged use, leading to decreased downtime and lower replacement costs.

Energy Efficiency

By optimizing the torque transmission and reducing the need for excessive force, reaction arm kit gear reducers can contribute to energy efficiency. This optimization ensures that machinery operates more smoothly and requires less power to achieve the desired performance, potentially leading to significant energy savings over time.

Easy Integration and Customization

Reaction arm kit gear reducers can be designed and customized to fit specific applications, making integration into existing systems straightforward. This flexibility ensures that regardless of the complexity or uniqueness of the machinery, there is always a solution that can enhance its performance through precise torque control and stability.

The benefits of using reaction arm kit gear reducers underscore their importance in modern industrial operations. By offering enhanced precision, increased stability, improved safety, versatility, durability, energy efficiency, and ease of integration, these components play a crucial role in optimizing the performance and reliability of a wide array of machinery. For industries looking to improve their operations, reduce costs, and enhance safety, incorporating reaction arm kit gear reducers is a step in the right direction.

Key Considerations

When selecting a reaction arm kit gear reducer, several factors need to be considered to ensure it meets the specific needs of the application. These include the required torque level, speed reduction ratio, compatibility with existing machinery, and environmental conditions in which the machinery operates.

The reaction arm kit gear reducer is a critical component in many mechanical systems, providing precise torque control and enhancing the efficiency and durability of machinery. Understanding its function, applications, and benefits can help engineers and technicians make informed decisions when designing or upgrading mechanical systems.