Gear reducers, fundamental to the operation of a wide range of machinery, serve a critical function in today's industrial and mechanical landscapes. These devices adeptly modify motor speed to meet specific operational needs, optimizing performance across various applications. This article aims to dissect the concept of gear reducers comprehensively, diving into their working principles, types, applications, selection processes, and maintenance protocols, all while maintaining a clear and accessible language.

Understanding the Core of Gear Reducers

The Fundamental Role of Gear Reducers

At the simplest level, a gear reducer is a mechanical device designed to decrease the speed while increasing the torque output from a power source to a driven mechanism or machine. This balance between speed reduction and torque amplification is essential in numerous mechanical applications, ensuring machines operate within their optimal performance ranges.

How Gear Reducers Operate

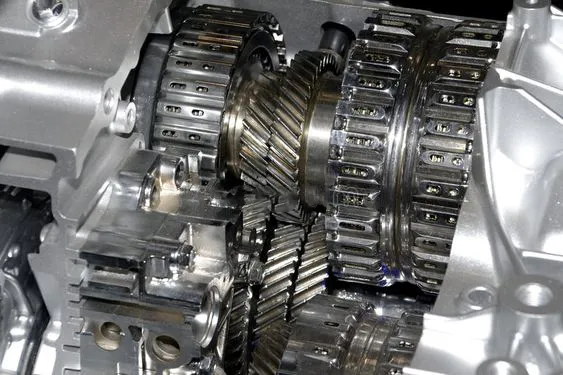

The operation of a gear reducer centers around three pivotal components:

- Input Shaft: This is where the power enters the reducer. Connected directly to the power source, usually an electric motor, it transmits the initial speed and torque into the reducer.

- Gears: The core of the reducer's functionality lies in its gears. Depending on the type (spur, helical, bevel, worm, or planetary), these gears interact to alter the motor's output. The configuration and ratio of these gears dictate the extent of speed reduction and torque increase.

- Output Shaft: Finally, the modified speed and torque are delivered to the machine via the output shaft, completing the transformation process.

The gear ratio, a critical aspect of this process, represents the relationship between the speeds of the input and output shafts, effectively determining the magnitude of speed reduction and torque amplification.

Diverse Types of Gear Reducers

The variety in gear reducer types underscores their adaptability across different mechanical realms, each offering unique advantages:

- Spur Gear Reducers: Known for their simplicity and efficiency in low-speed, high-torque applications, despite the potential for noise due to straight teeth engagement.

- Helical Gear Reducers: Their angled teeth allow for quieter operation and are suitable for applications where noise reduction is crucial.

- Bevel Gear Reducers: Ideal for changing rotational direction, these reducers use conical gears to transmit power at various angles.

- Worm Gear Reducers: Marked by a high reduction ratio, these offer a compact solution for space-limited applications but may suffer from lower efficiency.

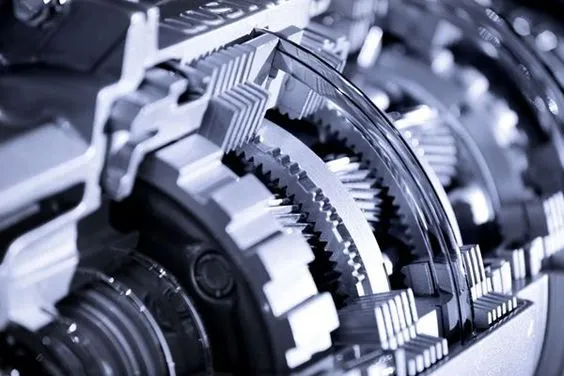

- Planetary Gear Reducers: Characterized by their central sun gear surrounded by planet gears, they are lauded for their efficiency and high torque output in a compact form.

The Wide Application Spectrum of Gear Reducers

Gear reducers are indispensable in numerous fields, demonstrating their versatility:

- Automotive: They adjust the torque and speed in transmission systems for better vehicle performance.

- Manufacturing: In conveyor systems, they regulate the belt speed to match production requirements.

- Robotics: Gear reducers provide the precise control needed for robotic mechanisms to function accurately.

- Renewable Energy: In wind turbines, they convert slow blade rotation into faster, usable energy output.

Selecting the Right Gear Reducer

Choosing an appropriate gear reducer is a nuanced decision, influenced by several key factors:

- Torque and Speed Requirements: The reducer must accommodate the application's peak torque demands while delivering the desired speed output.

- Efficiency: Higher efficiency units are preferable for energy savings and prolonged service life.

- Physical Constraints: The selected reducer should fit within the available space and comply with any physical installation limitations.

- Operating Conditions: The environmental and operational conditions, such as temperature, humidity, and load fluctuations, should inform the selection to ensure durability and reliability.

Maintenance Protocols for Gear Reducers

Regular and preventive maintenance is paramount to prolonging the life and ensuring the continuous efficiency of gear reducers. Key practices include:

- Lubrication: Regular lubrication reduces wear and friction, crucial for the longevity of moving parts.

- Inspection: Routine checks for signs of wear, damage, or misalignment can preempt failures.

- Part Replacement: Timely replacement of worn or damaged components prevents more significant issues down the line.

Gear reducers play a silent yet indispensable role in the seamless operation of machinery across industries. This guide has traversed the essentials of gear reducers, from their operational principles and types to their diverse applications, selection criteria, and maintenance. Armed with this knowledge, engineers, technicians, and enthusiasts can better appreciate the nuances of gear reducers, ensuring their optimal use in enhancing machine efficiency and performance. Whether for industrial, automotive, renewable energy, or robotic applications, understanding gear reducers is key to unlocking the potential of modern machinery.

Broader Implications and Advanced Considerations

The Impact of Gear Reducers on Industry Efficiency

The strategic deployment of gear reducers across various sectors—from automotive to renewable energy—demonstrates their pivotal role in enhancing operational efficiency and energy savings. By optimizing the speed and torque of machinery to match specific tasks, gear reducers not only improve performance but also contribute to significant energy conservation, a critical factor in today's eco-conscious industrial landscape.

Advanced Materials and Design Innovations

The evolution of gear reducers has been marked by advancements in materials science and design techniques. The use of lighter, more durable materials like composite metals or polymers can reduce the weight and increase the lifespan of gear reducers. Additionally, innovative design approaches, such as 3D printing, are being explored to manufacture gear parts with complex geometries that were previously impossible to create, further enhancing performance and efficiency.

Integration with Smart Technologies

The integration of gear reducers with IoT (Internet of Things) and predictive analytics represents a frontier in machinery maintenance and operation. Smart sensors embedded in gear reducers can monitor operational parameters in real-time, predicting maintenance needs before failures occur and optimizing performance based on immediate feedback. This integration heralds a shift towards more autonomous, self-optimizing machinery, underscoring the dynamic nature of gear reducer applications in the age of Industry 4.0.

Selection Sophistication: Beyond Basics

While the fundamental criteria for selecting a gear reducer—such as torque requirements, efficiency, and physical constraints—remain paramount, modern applications demand a deeper level of sophistication. Factors like compatibility with digital monitoring systems, adaptability to rapid shifts in operational demands, and compliance with increasingly stringent environmental regulations are becoming equally crucial in the selection process.

Sustainability and Gear Reducers

As industries worldwide strive for greater sustainability, the role of gear reducers in achieving energy-efficient operations gains prominence. The design and selection of gear reducers now increasingly consider not just immediate performance requirements but also long-term environmental impacts, including energy consumption and materials used in manufacturing processes.

Looking Ahead: The Future of Gear Reducers

The future of gear reducers lies in the balance of tradition and innovation. While the basic principles that govern their operation remain unchanged, the application of cutting-edge technologies and materials, along with a growing emphasis on sustainability and efficiency, is set to redefine their role in machinery and industry.

This exploration into the world of gear reducers underscores not just their technical and operational aspects but also their evolving role in a rapidly changing industrial landscape. As we push the boundaries of what is possible with modern machinery, gear reducers stand as a testament to the blend of enduring mechanical principles and innovative approaches to design and functionality. Their continued evolution will undoubtedly play a critical role in shaping the future of technology, industry, and sustainable practices worldwide.