The gearbox is an integral component of any vehicle, a masterpiece of mechanical engineering designed to translate the engine's power into motion. This critical piece of your car's drivetrain plays a vital role in determining performance, efficiency, and the overall driving experience. Whether manual or automatic, the gearbox ensures that your vehicle can navigate a variety of speeds and terrains with ease. By delving into the workings, types, and maintenance of gearboxes, we aim to shed light on their indispensable function within the automotive world.

Section 1: The Basics of a Gearbox

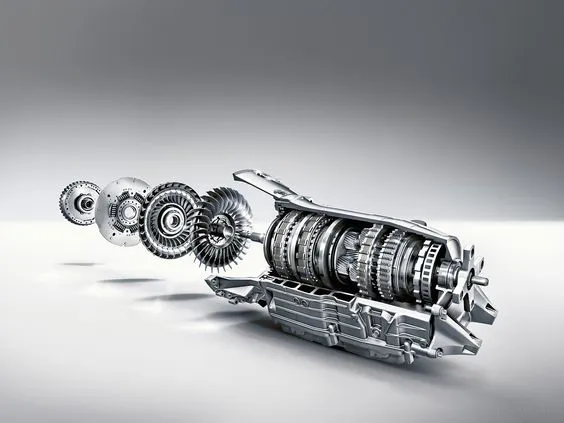

At the heart of vehicle performance is the gearbox, an ingenious mechanism tasked with an essential function: managing the distribution of power from the engine to the wheels. It achieves this through the use of gears and gear trains to provide speed and torque conversions.

- Functionality: The gearbox adjusts the engine's rotational speed, converting it into torque (twisting force) to move the vehicle forward or backward. It's this conversion process that allows cars to accelerate from a standstill to cruising speed in a smooth, controlled manner.

- How It Works: Imagine riding a bicycle: on flat ground, you use a gear that requires less effort to pedal, akin to a car's higher gear for cruising at speed. Conversely, climbing a hill, you switch to a lower gear for more force, similar to how a car downshifts to ascend a slope. The gearbox facilitates these transitions seamlessly, ensuring the engine operates efficiently across different speeds.

Section 2: Types of Gearboxes

The diversity in gearbox types caters to the vast range of vehicles and driving preferences today, each with its unique advantages.

- Manual Gearbox: Favoured for the control it offers drivers, requiring manual gear shifts with a clutch pedal. It's often celebrated for the engagement and driving pleasure it provides, especially in sports cars.

- Automatic Gearbox: Known for its convenience, it uses a torque converter to automatically select the appropriate gear. Its ease of use has made it a popular choice in many modern vehicles, providing a relaxed driving experience, particularly in urban settings.

- Semi-Automatic and Dual-Clutch Gearboxes: These systems combine manual and automatic features, offering quick shifts and reduced power loss during gear changes. Dual-clutch transmissions, in particular, are praised for their efficiency and performance, making them a choice for high-performance vehicles.

- Continuously Variable Transmission (CVT): This type eliminates the traditional gears for a belt and pulley system, providing an infinite range of ratios. The result is a smooth acceleration without the noticeable gear changes, optimizing fuel efficiency and performance.

Section 3: Importance of the Gearbox

The gearbox's contribution to a vehicle's operation is multifaceted, impacting not just the driving dynamics but also the vehicle's efficiency.

- Performance: By ensuring the engine remains within its optimal RPM range, the gearbox can deliver maximum performance, allowing for swift acceleration and responsive handling.

- Fuel Efficiency: Effective gear management means the engine can perform efficiently without unnecessary strain, directly influencing fuel consumption and emissions.

- Driver Control: Manual gearboxes, in particular, afford drivers the ability to directly influence the vehicle's power output, enhancing the connection between driver and machine.

Section 4: Common Gearbox Problems and Maintenance

Maintaining a gearbox is crucial for vehicle longevity and reliability. Awareness of common issues and adherence to maintenance schedules can prevent costly repairs.

- Common Problems: Symptoms of gearbox troubles can range from difficulty in gear selection to audible complaints from the gearbox itself, such as grinding or whining noises. These issues may stem from a variety of causes, including worn gear components, inadequate lubrication, or clutch malfunctions in manual transmissions.

- Maintenance Tips: Regular inspections and fluid changes are paramount. For manual gearboxes, mindful driving and proper use of the clutch can extend its life. In automatic transmissions, avoiding excessive strain, such as towing beyond the vehicle's capacity, helps prevent wear.

Preventative Maintenance: Regular and preventive maintenance is key to ensuring the longevity and reliability of any gearbox. Vehicle owners should adhere to the manufacturer's recommended service intervals, which often include:

- Transmission Fluid Check and Replacement: One of the most crucial maintenance tasks. The health of the gearbox is heavily dependent on the quality and level of the transmission fluid, as it lubricates, cools, and cleans internal components. For most vehicles, checking the transmission fluid monthly and following the manufacturer's guidelines for replacement can prevent many common gearbox issues.

- Listening for Warning Signs: Paying attention to the sounds your car makes can help catch gearbox issues early. Whining, clunking, or grinding noises during gear changes are clear indicators that a professional inspection is necessary.

- Professional Inspections: Even with diligent personal maintenance, having a professional mechanic inspect the gearbox can catch issues that aren't obvious to most drivers. This can include diagnostic checks to ensure the gearbox is communicating properly with the rest of the vehicle in more advanced automatic and semi-automatic systems.

Section 5: Innovations in Gearbox Technology

The rapid pace of automotive innovation promises significant advancements for gearbox technology, particularly in response to the global push towards electrification and automation.

- Electrification: Electric vehicles (EVs) and hybrids represent a shift in how gearboxes are designed and function. EVs often require fewer gears due to the electric motor's wide RPM range. However, the development of multi-speed transmissions for EVs aims to further optimize efficiency and performance, particularly at high speeds.

- Intelligent Gearboxes: The future of gearboxes lies in smarter, more adaptive systems. Advances in artificial intelligence and machine learning allow for gearboxes that can anticipate the driver's next move and adjust accordingly, optimizing for fuel efficiency, performance, or driving comfort based on real-time conditions and driving habits.

- Sustainability: With a growing emphasis on sustainability, future gearbox designs will prioritize not just efficiency but also the use of environmentally friendly materials and manufacturing processes. This aligns with the automotive industry's broader goals of reducing carbon footprints and promoting sustainable mobility solutions.

The gearbox is a cornerstone of automotive design, a testament to the ingenuity and innovation that drive the industry forward. From the basic principles of gear selection to the complexities of modern automatic and semi-automatic systems, the gearbox plays a pivotal role in defining a vehicle's character and capabilities. As technology advances, the evolution of gearbox designs continues to push the boundaries of efficiency, performance, and sustainability, ensuring that this vital component remains at the heart of automotive engineering for years to come. Whether through improved maintenance techniques or breakthroughs in gearbox technology, the future promises vehicles that are more enjoyable to drive, easier to maintain, and kinder to our planet.

FAQs

- Can driving style affect the lifespan of a gearbox? Yes, aggressive driving, such as rapid acceleration and deceleration, can strain the gearbox, leading to premature wear. Adopting a smoother driving style can extend the life of the gearbox.

- What's the difference between a gearbox and a transmission? The terms are often used interchangeably in automotive contexts. Technically, a gearbox is a part of the transmission system, which includes the clutch, gearbox, differential, and driveshaft.

- How often should transmission fluid be checked or changed? This varies by vehicle and transmission type, but a general rule of thumb is to check the fluid level monthly and follow the manufacturer's recommendation for fluid changes, typically every 30,000 to 60,000 miles for most vehicles.