Begin with an engaging hook that draws the reader into the subject. Explain the ubiquitous yet often overlooked role of gear reducers in modern technology. Set the stage for the article by promising an exploration into their functionality, types, applications, and maintenance aimed at a broad audience.

Understanding Gear Reducers

Definition

Detail what gear reducers are, emphasizing their role in converting high-speed, low-torque input into low-speed, high-torque output. Use layman's terms to describe how this process is essential for various mechanical applications.

Dive into the mechanics of gear reducers, using diagrams or animations if possible. Explain the concept of gear ratios and how altering these ratios changes the output speed and torque. Discuss energy conservation within this context and debunk common misconceptions about power loss.

How Gear Reducer Works

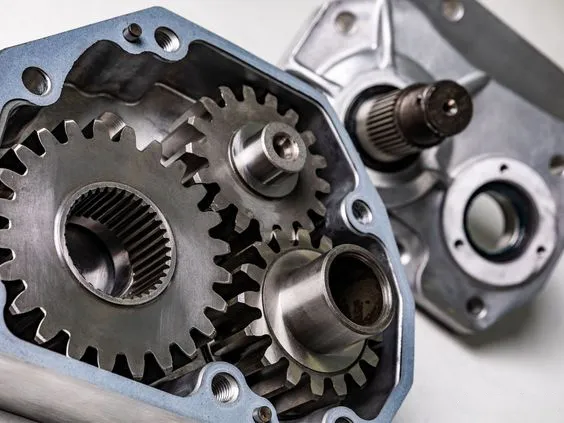

A gear reducer, also known as a gearbox, works by adjusting the speed and torque of a motor to match the requirements of a particular application. The basic principle behind a gear reducer is relatively straightforward: it takes the high-speed, low-torque input from a motor. It converts it into a lower-speed, higher-torque output. This process involves a series of gears or gear trains that leverage mechanical advantage to achieve the desired reduction in speed and a corresponding increase in torque. Here's a closer look at how this process works:

Basic Components

- Input Shaft: Connected to the power source (e.g., an electric motor). This shaft transmits the input power to the gearbox.

- Gears: Gear reducers contain at least two gears: a smaller gear (the “pinion”) and a larger gear (the “gear” or “wheel”). The size difference and gear ratio between these gears determines the reduction in speed and increase in torque.

- Output Shaft: This shaft is connected to the larger gear and delivers the reduced-speed, increased torque output to the machine or equipment being driven.

Working Principle

- Transmission of Power: The input shaft, driven by the motor, transmits its rotational speed to the pinion (the smaller gear).

- Speed Reduction and Torque Increase: As the pinion rotates, it meshes with the larger gear, causing it to turn. Because the larger gear has more teeth than the pinion, it turns more slowly. This reduction in speed (or increase in the time it takes for the gear to make a full rotation) translates directly into an increase in torque, according to the law of conservation of energy. The specific reduction in speed and increase in torque are determined by the gear ratio, which is the ratio of the number of teeth on the larger gear to the number of teeth on the pinion.

- Output Delivery: The larger gear is connected to the output shaft, which then delivers the reduced speed and increased torque to the machine or equipment.

Types of Gear Reducers

Gear reducers are crucial components in many mechanical systems, helping to adjust the torque and speed transmitted from one shaft to another. They come in various types, each with its own set of characteristics and applications. Here are the most common types of gear reducers:

- Spur Gear Reducers: These are the simplest type, consisting of cylindrical gears with parallel input and output shafts. They are known for their efficiency and high power transmission capability but can be noisy due to the direct contact between gear teeth.

- Helical Gear Reducers: Similar to spur gears but with teeth that are cut at an angle to the face of the gear. This design allows for more gradual engagement of the gear teeth, leading to smoother and quieter operation. They can transmit power between parallel or crossed shafts.

- Bevel Gear Reducers: Used to change the direction of shaft rotation, bevel gears have conical teeth and can transfer power between shafts that intersect at an angle, usually 90 degrees. They are often used in differential drives.

- Worm Gear Reducers: Consist of a worm (screw) that meshes with a worm wheel (gear). They can greatly reduce speed and increase torque in a compact size but tend to have lower efficiency due to sliding contact between the teeth.

- Planetary (Epicyclic) Gear Reducers: These feature a central ‘sun' gear, several ‘planet' gears that rotate around it, and an outer ring gear. They offer high torque density, compact size, and excellent efficiency but are more complex and expensive.

- Harmonic Gear Reducers: Utilize a flexible gear and a rigid circular spline to achieve high reduction ratios in a very compact design. They are known for their precision but are typically used in lower power applications.

- Cycloidal Gear Reducers: Operate using a cycloidal disk that engages with pins on the housing and an output shaft, achieving high reduction ratios and torque transmission in a compact design. They are highly durable and resistant to shock loads.

Each type of gear reducer has its unique advantages, making it suitable for specific applications. The choice of gear reducer depends on factors like the required torque, speed reduction ratio, efficiency, space constraints, and noise level.

Applications of Gear Reducers

Gear reducers are fundamental components in various industries, serving critical roles in many mechanical systems by adjusting the output speed and torque of engines or motors to meet specific requirements. Their versatility allows for widespread application across different fields:

- Manufacturing Industry: Gear reducers are pivotal in manufacturing equipment such as conveyors, assembly lines, and packaging machines. They adjust the speed of motors to suit different phases of the production process, enhancing efficiency and control.

- Automotive Sector: In automotive engineering, gear reducers are used in transmissions to convert engine power into a form that's usable by the wheels, allowing for speed variation and control. Differential gears, a type of gear reducer, enable the wheels to rotate at different speeds, which is essential for turning.

- Aerospace and Aviation: Gear reducers are employed in aircraft systems for controlling flap and landing gear deployment, as well as in adjusting fan speeds in jet engines, ensuring optimal performance and safety.

- Renewable Energy: In wind turbines, gear reducers transform the slow, high-torque motion of the turbine blades into faster rotations that are more suitable for generating electricity, maximizing efficiency.

- Robotics and Automation: Precision is key in robotics, where gear reducers like planetary and harmonic drives provide the necessary torque and speed control for movements, from industrial robots to medical devices.

- Agriculture Machinery: Tractors, plows, and harvesters use gear reducers to translate the engine's power into workable speeds for various tasks, improving both efficiency and effectiveness.

- Marine Applications: Ships and boats use gear reducers to adjust engine output for propelling and steering, ensuring navigational control and fuel efficiency.

- Construction and Mining Equipment: Heavy machinery such as excavators, bulldozers, and conveyor systems rely on gear reducers to handle the demanding tasks of digging, moving, and processing materials.

- Water Treatment Plants: Pumps and blowers in water treatment facilities use gear reducers to manage flow rates and pressures, crucial for efficient water processing.

- Entertainment Industry: Gear reducers are used in the mechanical systems of amusement park rides and stage equipment, providing the necessary control for safe and enjoyable experiences.

Each application benefits from the specific characteristics of gear reducers, such as their ability to provide high torque at low speeds, improve system efficiency, reduce mechanical wear, and offer precise control. The choice of gear reducer type (spur, helical, worm, bevel, planetary, etc.) depends on the specific requirements of the application, including space constraints, noise levels, efficiency needs, and cost considerations.

Benefits of Using Gear Reducers

Expand on each benefit listed, providing examples and real-world scenarios where gear reducers enhance system efficiency, durability, control, and versatility. This could include case studies or comparative analyses showing systems with and without gear reducers.

Selecting the Right Gear Reducer

Selecting the right gear reducer is crucial for achieving optimal performance, efficiency, and reliability in your mechanical system. Here are the key factors and steps involved in selecting the appropriate gear reducer for your application:

Determine Application Requirements

- Torque and Speed: Calculate the required output torque and speed based on the load and the operational parameters of the application. This will help in determining the necessary reduction ratio.

- Reduction Ratio: The ratio between the input speed (motor speed) and the desired output speed. It can be calculated by dividing the input speed by the output speed.

- Power and Efficiency: Consider the power that needs to be transmitted through the gearbox and the efficiency of the gear reducer, which affects the overall performance and energy consumption.

Select Gear Reducer Type

Based on the application's requirements and constraints, decide on the type of gear reducer:

- Spur and Helical Gear Reducers for applications requiring high power transmission and efficiency with parallel shafts.

- Bevel Gear Reducers for changes in shaft direction, typically at right angles.

- Worm Gear Reducers for high reduction ratios, compact spaces, and when non-backdrivability is required.

- Planetary Gear Reducers for compact spaces requiring high torque and efficiency.

- Harmonic and Cycloidal Reducers for precision applications requiring very high reduction ratios and compactness.

Consider Design and Operational Factors

- Mounting Configuration: Select a gearbox that fits the physical space and mounting requirements of your application.

- Backlash: Consider the amount of backlash (play between mating teeth) acceptable for your application, especially important in precision motion control.

- Load Capacity and Service Factor: Ensure the gearbox can handle the maximum load and has an appropriate service factor for its expected duty cycle and operational conditions. The service factor is a multiplier that provides a safety margin based on the application's severity and duration of operation.

- Material and Construction: Consider the materials and construction quality of the gear reducer for durability, especially in harsh environments.

- Maintenance and Lifespan: Evaluate the maintenance requirements and expected lifespan of the gearbox. Some types require more maintenance than others.

Evaluate Suppliers and Product Lines

- Research different manufacturers and suppliers to compare their product lines, support services, customization options, and lead times.

- Consider the reputation of the manufacturer and the experiences of other users in similar applications.

Finalize Selection with Calculations and Verification

- Perform detailed calculations or simulations, if necessary, to verify the suitability of the selected gear reducer for the specific application parameters.

- Consult with engineers or the manufacturer's technical support to review your selection and confirm that all application requirements are met.

Choosing the right gear reducer involves a balance between technical specifications, operational needs, and cost considerations. Proper selection ensures reliability, efficiency, and longevity of the mechanical system.

Maintenance and Care

Provide a detailed maintenance guide that includes:

- Lubrication: Types of lubricants, frequency of lubrication, and methods.

- Inspection: Checklist of signs of wear or failure and routine inspection schedules.

- Cleaning: Recommended practices for keeping gear reducers clean and functional.

Highlight the importance of regular maintenance in preventing downtime and extending the life of the equipment.