In the realm of automotive engineering, the sequential gearbox represents a fascinating blend of performance, precision, and technological innovation. Unlike traditional manual transmissions with their characteristic H-pattern, sequential gearboxes allow drivers to shift gears in sequence, either up or down, without skipping gears. This article delves into the sequential gearbox, explaining its operation, benefits, applications, and how it compares to other types of transmissions.

The Basics of a Sequential Gearbox

- Definition: A sequential gearbox is a type of transmission used primarily in motorcycles and high-performance vehicles where gears are selected in order, either upshifting or downshifting.

- How It Works: Detail the mechanism of a sequential gearbox, emphasizing the linear shift pattern that distinguishes it from conventional manual transmissions. The section should explain the gear engagement process, typically involving a single lever or paddle shifters connected electronically or mechanically to the gearbox.

Components and Operation

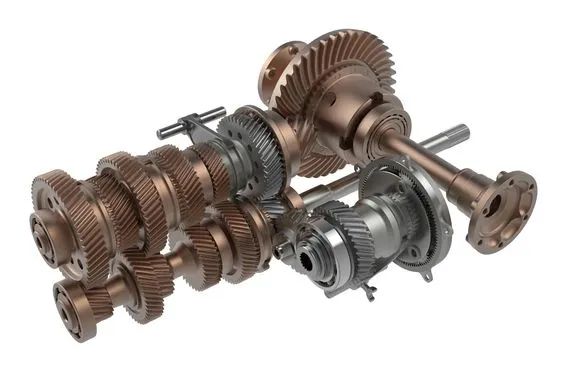

- Key Components: Describe the primary components of a sequential gearbox, including the shift drum, selector forks, and gear sets. Illustrate how these parts interact to facilitate gear changes.

- Operation: Break down the step-by-step process of shifting gears in a sequential gearbox, from the driver's input to the mechanical or electronic actuation of gear changes.

Advantages of Sequential Gearboxes

- Speed and Efficiency: Discuss how sequential gearboxes allow for quicker shifts, reducing time spent between gears and enhancing overall vehicle performance.

- Simplicity and Reliability: Explore how the straightforward design of sequential gearboxes leads to increased reliability and easier maintenance compared to more complex transmission systems.

- Enhanced Control: Highlight how sequential gearboxes provide drivers with better control over their vehicle's power output, especially in racing or performance driving scenarios.

Applications of Sequential Gearboxes

- Motorsports: In the high-stakes world of motorsport, the efficiency and speed of gear changes are crucial. Sequential gearboxes are a staple in this environment due to their ability to execute rapid gear shifts. This quick shifting is vital for racing cars, where every millisecond counts, allowing drivers to maintain higher speeds and smoother acceleration throughout races. The reliability and straightforward operation of sequential gearboxes also reduce the likelihood of miss-shifts, a common issue in manual transmissions that can lead to significant time loss or mechanical failures.

- Motorcycles: The design and operational benefits of sequential gearboxes are particularly suited to motorcycles. Their compact size and linear shifting mechanism allow for a more straightforward integration into the motorcycle's design, optimizing space and reducing weight. The ease of use is another significant advantage for riders, especially in performance or off-road scenarios, where maintaining control and focus on the environment is paramount. The natural up-and-down motion of the gear lever on a motorcycle is intuitive, even with the added complexity of clutch operation, making it a preferred choice for many riders.

- High-Performance Cars: While less common in everyday passenger vehicles, sequential gearboxes have carved out a role in high-performance and sports cars. Enthusiasts appreciate the enhanced driving experience provided by the tactile feedback and control of sequential shifting. These gearboxes allow for a more engaged driving experience, where the driver has direct control over gear selection without the complexity and physical demand of a traditional manual clutch. The performance benefits, such as quicker acceleration and the ability to maintain optimal engine power, make sequential gearboxes a feature in cars designed for speed and agility.

Comparison with Other Transmissions

Understanding how sequential gearboxes compare with other transmission types helps highlight their unique position in the automotive world:

- Manual vs. Sequential: Traditional manual transmissions offer the driver complete control over gear selection, with the iconic H-pattern shift being a hallmark of this design. However, sequential gearboxes streamline this process, offering a simpler, back-and-forth gear selection method. This not only reduces the likelihood of miss-shifts but also allows for faster gear changes. While manual transmissions might provide a more ‘authentic' driving experience for purists, sequential gearboxes offer a blend of control and efficiency that appeals to performance drivers.

- Automatic vs. Sequential: Automatic transmissions prioritize convenience and ease of use, handling all gear shifting decisions based on engine load and speed. While this ensures a comfortable drive, particularly in urban or congested environments, it can sometimes detach the driver from the driving experience. Sequential gearboxes, by allowing manual gear selection without the need for a clutch pedal, give drivers a middle ground. They can enjoy the engagement of shifting gears manually when desired, without the physical demands associated with a clutch, combining performance with convenience.

Maintenance and Common Issues

Maintaining a sequential gearbox is crucial for its performance and longevity:

- Maintenance Tips: Regular maintenance of a sequential gearbox includes checking and replacing transmission fluid at manufacturer-recommended intervals, inspecting for leaks, and ensuring that the electronic systems managing the gearbox are functioning correctly. Given the mechanical and electronic complexity of sequential gearboxes, professional servicing is often necessary to address issues that go beyond routine maintenance.

- Common Problems: Sequential gearboxes can experience wear and tear on their components, such as selector forks, which are crucial for changing gears. Electronic or hydraulic actuation systems can also fail, leading to delayed or missed gear changes. Regular diagnostics can help identify these problems early, preventing further damage and maintaining the gearbox's performance.

- Long-Term Care for Sequential Gearboxes: To ensure the longevity of a sequential gearbox, it's essential to adhere to a proactive maintenance schedule. This includes routine inspections for wear and tear on critical components such as gears, bearings, and the shift actuator system. Regular software updates, for models that rely on electronic control units, can optimize gearbox performance and address any emerging issues.

Diagnostic Checks: With the advancement in vehicle diagnostics, many potential problems within a sequential gearbox can be preemptively identified through electronic scanning and diagnostics. This modern approach allows for a more precise maintenance regime, targeting specific components that may require attention or adjustment.

Addressing Common Problems: Among the typical challenges encountered with sequential gearboxes are issues related to harsh shifting, delayed gear engagement, or unexpected gear disengagement. These problems often stem from hydraulic pressure anomalies, sensor malfunctions, or wear and tear on the shift forks and gears. Prompt attention to these symptoms not only ensures the gearbox's operational integrity but also safeguards against more extensive, costly repairs down the line.

The Future of Sequential Gearboxes

The automotive industry's shift towards electrification and advanced driver-assistance systems (ADAS) poses new challenges and opportunities for sequential gearbox technology. Innovations in materials science and electronics may lead to lighter, more efficient sequential gearboxes that can handle the instant torque of electric motors and integrate seamlessly with hybrid powertrains. As vehicles become more connected and autonomous, the role of the gearbox may evolve, but the demand for engaging driving experiences will continue to drive advancements in sequential gearbox technology.

- Technological Advancements: Speculate on future developments in sequential gearbox technology, including potential improvements in materials, electronics, and integration with hybrid and electric powertrains.

- Market Trends: Discuss how evolving automotive trends and consumer preferences might influence the use and design of sequential gearboxes in future vehicles.

Summarize the key points covered, reinforcing the unique advantages and applications of sequential gearboxes in the automotive landscape. Emphasize the role of sequential gearboxes in enhancing vehicle performance and driving pleasure, while also acknowledging the technological innovations that may shape their future.

FAQs

- Are sequential gearboxes suitable for everyday driving? Yes, while known for their performance attributes, modern sequential gearboxes offer driving modes that cater to both dynamic driving and everyday comfort, making them versatile for various driving scenarios.

- How do I know if my sequential gearbox needs servicing? Key indicators include difficulty in shifting gears, unusual noises during operation, or the check engine light turning on, signaling it's time for a diagnostic check.

- Can upgrading a sequential gearbox improve vehicle performance? Upgrades and fine-tuning can enhance performance, especially if tailored to the specific characteristics of the vehicle and driving conditions. However, it's vital to consult with specialists to ensure compatibility and maintain vehicle integrity.