The maintenance of agricultural and landscaping equipment is crucial for ensuring their efficiency and durability. Among these tools, the bush hog, a heavy-duty rotary cutter used for clearing brush and overgrown areas, plays a pivotal role. Central to the bush hog's operation is its gearbox, which facilitates the transfer of power from the engine to the cutting blades. This article delves into the significance of selecting the correct weight (viscosity) of oil for the bush hog gearbox, a decision that can significantly impact the equipment's performance and lifespan.

Bush Hog Gearbox Basics

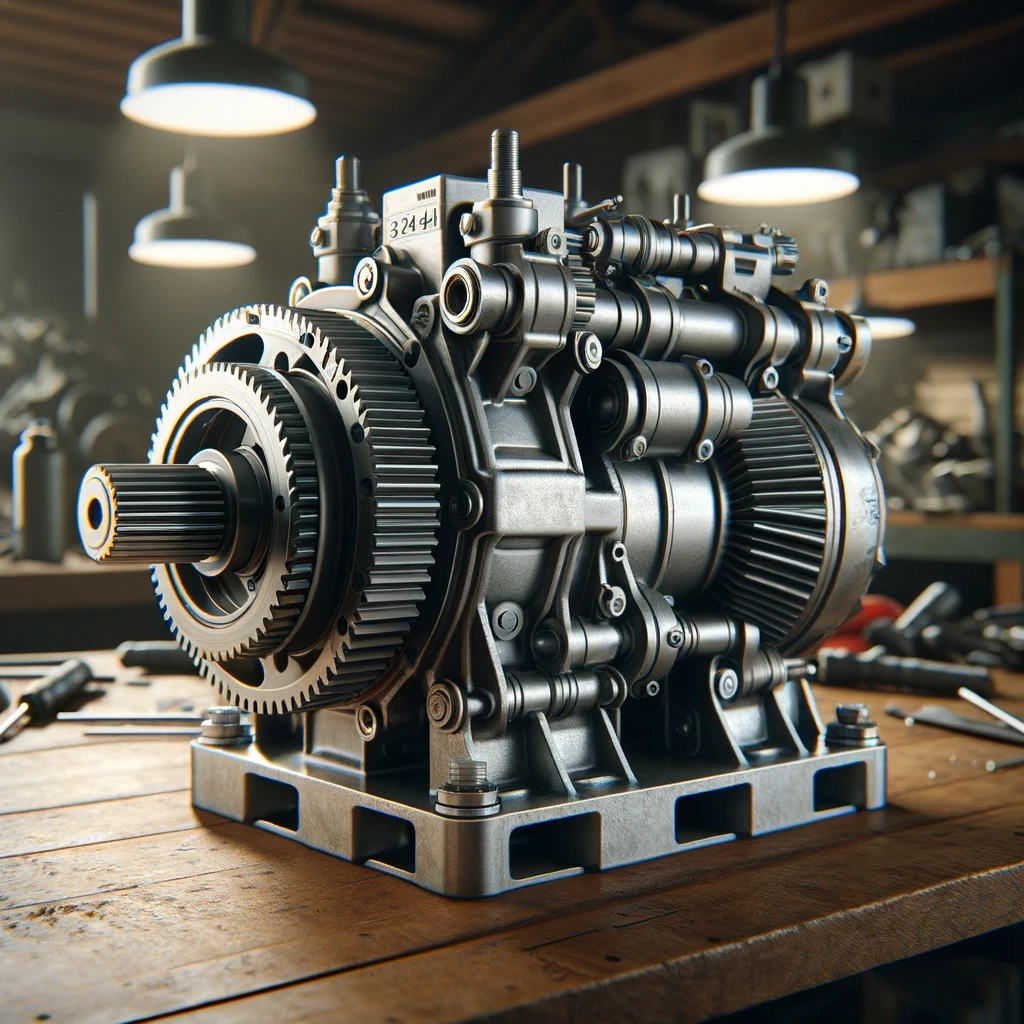

A bush hog gearbox is a specialized component designed to convert the power generated by the engine into the rotary motion needed to drive the cutting blades. Understanding its construction and operation is essential for anyone responsible for the maintenance of a bush hog. The gearbox houses gears, bearings, and seals, all of which require proper lubrication to function efficiently and prevent wear and overheating.

The Importance of Lubrication

Lubrication in a gearbox serves several critical functions: it reduces friction between moving parts, aids in heat dissipation, and helps in preventing wear and corrosion. The choice of lubricant, particularly its weight or viscosity, plays a crucial role in ensuring these functions are performed optimally. Viscosity refers to the oil's resistance to flow, with higher weights indicating thicker oils that flow more slowly.

Choosing the Right Oil Weight

Selecting the appropriate oil weight for a bush hog gearbox is dependent on several factors, including the operating environment and temperature. Manufacturers often provide recommendations for oil weight based on the expected temperature range during operation. Adhering to these recommendations is crucial for ensuring the longevity and reliability of the gearbox.

Common Types of Lubricants and Their Applications

Lubricants can be broadly classified into mineral oils and synthetic oils, each with specific characteristics suited to different applications. Mineral oils, derived from petroleum, are commonly used and offer good protection in a wide range of operating conditions. Synthetic oils, on the other hand, are engineered to provide superior performance, especially in extreme temperatures and conditions. The choice between these oils should be guided by the manufacturer's recommendations and the specific requirements of the equipment.

Maintenance and Oil Change Procedures

Regular maintenance, including oil changes, is essential for the optimal performance of a bush hog gearbox. The article would provide step-by-step instructions on how to change the gearbox oil, including the tools required, safety precautions, and tips for ensuring the procedure is conducted efficiently. Additionally, it would outline a maintenance schedule, recommending the frequency of oil changes and inspections to prevent common issues.

Troubleshooting Common Problems

Incorrect oil weight or poor maintenance practices can lead to several problems, such as overheating, excessive noise, or gear failure. This section would offer guidance on diagnosing and addressing common issues associated with bush hog gearboxes, emphasizing the importance of correct lubricant selection and regular maintenance.

Case Studies

Real-world examples serve to highlight the consequences of neglecting proper lubricant selection and maintenance. This section would present case studies illustrating the potential costs of using incorrect oil weight or neglecting gearbox maintenance, reinforcing the article's earlier points.

FAQ

Q1: How often should I change the oil in my bush hog gearbox?

- A1: It's recommended to follow the manufacturer's guidelines, but a general rule is to change the oil every year or after every 100 hours of use. If your equipment operates under extreme conditions, such as high temperatures or dusty environments, more frequent changes may be necessary.

Q2: How can I tell if the gearbox oil needs to be changed?

- A2: Check the oil's color and texture. If the oil becomes very dark or contains metal fragments, it might indicate wear or internal damage, necessitating a change. Oil that has thinned or smells burnt is also a sign that it needs to be replaced.

Q3: What's the difference between using synthetic oil and mineral oil?

- A3: Synthetic oil generally offers better temperature stability and wear protection, especially under extreme temperature conditions. Mineral oil is less expensive but may require more frequent changes. The choice between these oils should consider the working environment, equipment requirements, and cost factors.

Q4: What problems can incorrect oil weight cause?

- A4: Using oil that is too light can lead to inadequate lubrication and accelerated wear. Oil that is too heavy may cause the gearbox to overheat or make it difficult for the oil pump to circulate oil, affecting performance. The correct oil weight ensures proper lubrication and heat dissipation.

Q5: Can I mix different brands or types of gearbox oil?

- A5: It's best to avoid mixing different brands or types of oil. Different lubricants may have different additives, and mixing them could affect their performance. If you need to change oil types, it's preferable to completely drain the old oil before adding new oil.

Q6: How do I properly check the gearbox oil level?

- A6: Ensure the equipment is on a level surface. Most gearboxes have an inspection window or dipstick to check the oil level. The oil level should reach the recommended mark or fill to the midpoint of the inspection window.

Q7: Can I change the oil in my bush hog gearbox myself?

- A7: Yes, changing the oil in most equipment is a relatively simple process that requires basic tools and following the correct steps. Ensure you read and understand the manufacturer's instructions before starting to avoid damaging the equipment.

Q8: What should I do if I'm unsure about which oil weight to use?

- A8: First, refer to the equipment manufacturer's recommendations. If information is unavailable or you're working in a unique environment, consult a professional service technician or a lubricant supplier who can offer advice based on your specific needs.