- Briefly introduce the importance of maintaining agricultural equipment, focusing on the Bush Hog as a vital tool for farmers and landowners.

- Highlight the role of gearbox oil in preserving the functionality and longevity of Bush Hog gearboxes.

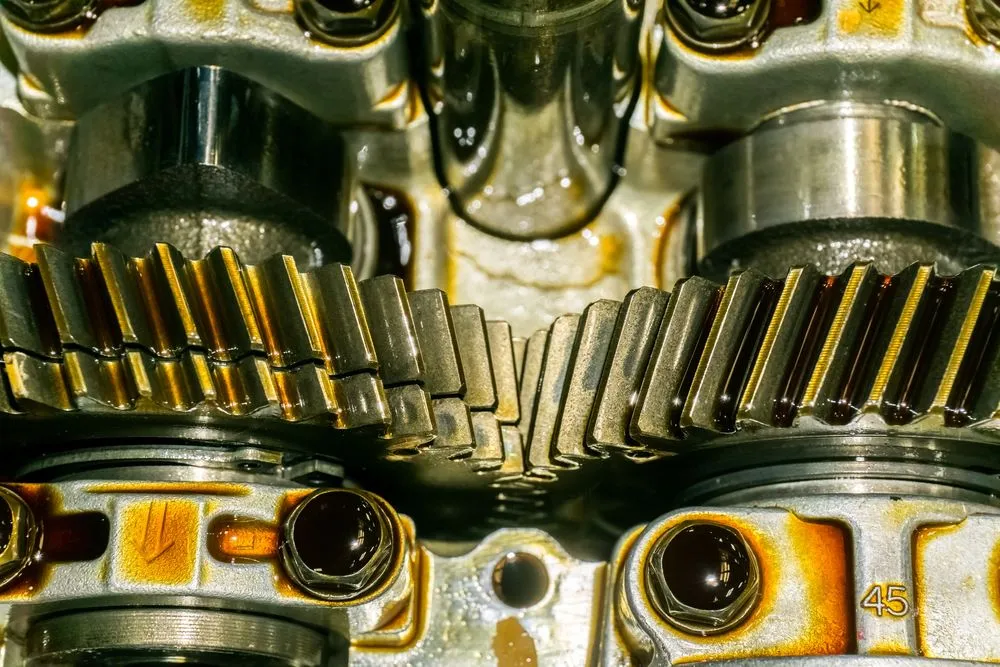

Understanding Bush Hog Gearboxes

The Role of the Gearbox in Bush Hog Operations

Why Oil Capacity Matters

- Link the concept of oil capacity with the efficient operation of Bush Hog gearboxes.

- Mention the potential risks of incorrect oil levels, such as overheating, wear, and failure.

Determining the Right Oil Capacity

Manufacturer Specifications

- Stress the importance of adhering to the manufacturer's recommended oil capacities.

- Suggest where to find this information (e.g., user manuals, official websites).

Factors Influencing Oil Capacity

- Discuss how model variations can affect oil capacity requirements.

- Mention the impact of operating conditions, such as temperature and terrain.

Choosing the Right Gearbox Oil

Types of Oil Suitable for Bush Hog Gearboxes

Selecting the right type of oil for a Bush Hog gearbox is crucial for maintaining its performance and longevity. The specific type of oil recommended can vary depending on the manufacturer's specifications, the operating environment, and the workload. However, there are several common types of oil that are generally suitable for use in Bush Hog gearboxes, each with its own benefits and applications.

Gear Oil

- SAE 80W-90 or SAE 85W-140: These are standard gear oils used in agricultural equipment gearboxes. The choice between them often depends on the climate and operating conditions, with SAE 80W-90 being suitable for general conditions and SAE 85W-140 for more extreme temperatures or heavy-duty use.

- Benefits: Provides excellent lubrication and protection against wear, especially under high loads and temperatures.

- Application: Suitable for most Bush Hog gearboxes, especially in regions with variable temperature ranges.

Synthetic Gear Oil

- ISO VG 220 or similar: Synthetic gear oils are designed for extreme conditions and offer superior performance over a wider temperature range than conventional oils.

- Benefits: Includes better thermal stability, reduced friction, and the ability to extend service intervals, making it an excellent choice for intensive use or in extreme environmental conditions.

- Application: Ideal for Bush Hog gearboxes used in very cold or very hot climates, or when extended service intervals are desired.

Universal Tractor Transmission Oil (UTTO)

- Multi-functional oil: Designed for use in tractors' transmissions, hydraulics, and wet brakes, UTTO can also be suitable for some Bush Hog gearboxes, particularly those that are part of a tractor's integrated system.

- Benefits: Provides good lubrication, protection against wear, and is compatible with a wide range of equipment.

- Application: Suitable for Bush Hogs that are used in conjunction with tractors where a single type of oil is preferred for all systems.

Extreme Pressure (EP) Gear Oil

- EP additives: These oils contain additives that provide additional protection against wear and tear in conditions of high pressure and load.

- Benefits: Prevents metal-to-metal contact under high loads, protecting gears from wear and pitting.

- Application: Best for heavy-duty Bush Hog gearboxes under extreme stress or for prolonged periods.

Considerations for Selecting Gearbox Oil

- Manufacturer's Recommendations: Always consult the Bush Hog's manual or manufacturer's recommendations first, as using the incorrect type of oil can lead to damage or reduced performance.

- Operating Environment: Consider the typical operating temperatures and conditions. In colder climates, oils with lower viscosity grades ensure better flow at low temperatures. For hotter climates or intense operation, higher viscosity or synthetic oils may provide better protection.

- Change Intervals: Synthetic oils generally allow for longer intervals between changes, but they are also more expensive. Balance the cost against the potential benefits and convenience.

The right gearbox oil is essential for the optimal performance and durability of a Bush Hog. Whether you choose conventional gear oil, synthetic formulations, UTTO, or EP gear oil, ensuring it meets the specific requirements of your equipment and operating conditions will help maintain the gearbox in top condition. Regular checks and changes according to the manufacturer's guidelines are vital for keeping your Bush Hog running smoothly and efficiently.

When to Change the Oil

- Offer guidelines on regular maintenance schedules for oil changes.

- Discuss signs that indicate the need for an oil change earlier than scheduled.

Step-by-Step Guide to Checking and Changing Gearbox Oil

Preparing Your Bush Hog for Maintenance

- Outline the steps to safely prepare the Bush Hog for maintenance (e.g., disengaging the PTO, securing the equipment).

Checking the Oil Level

- Provide a detailed guide on how to check the oil level, including tools needed and safety precautions.

- Explain how to interpret the oil level and what actions to take if the level is too low or too high.

Changing the Gearbox Oil

- Offer a step-by-step walkthrough for draining old oil, selecting the right oil, and refilling the gearbox to the correct capacity.

- Include tips for disposing of old oil responsibly.

Troubleshooting Common Gearbox Oil Issues

Recognizing and Addressing Leaks

- Describe how to identify oil leaks and possible causes (e.g., worn seals, damage).

- Provide advice on fixing leaks or when to seek professional help.

Dealing with Contaminated Oil

- Discuss the signs of oil contamination (e.g., discoloration, debris) and its impacts.

- Offer solutions for preventing contamination and actions to take if contamination is detected.

Enhancing Your Bush Hog's Performance and Longevity

Regular Maintenance Tips

- Summarize key maintenance practices beyond oil management to keep the Bush Hog in top condition.

- Emphasize the role of consistent care in extending the life of the equipment.

Professional Inspection and Service

- Advise on when and why to consider professional inspection and service for the Bush Hog gearbox.

- Mention the benefits of expert assessment, especially after heavy use or before storage.

Conclusion

- Recap the critical points about Bush Hog gearbox oil capacity, selection, and maintenance.

- Encourage readers to prioritize regular maintenance to ensure their Bush Hog remains a reliable asset for their agricultural needs.