In the world of agricultural and landscaping equipment, the Bush Hog stands out for its durability and performance in cutting through thick vegetation and brush. Central to its operation is the Bush Hog gearbox, a critical component that ensures the machine's cutting blades rotate effectively and reliably.

Understanding Bush Hog Gearboxes

What Is a Bush Hog Gearbox?

A Bush Hog gearbox is a mechanical component used in heavy-duty rotary cutters. It is also commonly known as “Bush Hogs” after the popular brand name that has become a generic term for these types of implements. The gearbox is a crucial part of the rotary cutter, as it transfers power from the tractor's PTO (Power Take-Off) to the cutter's blades.

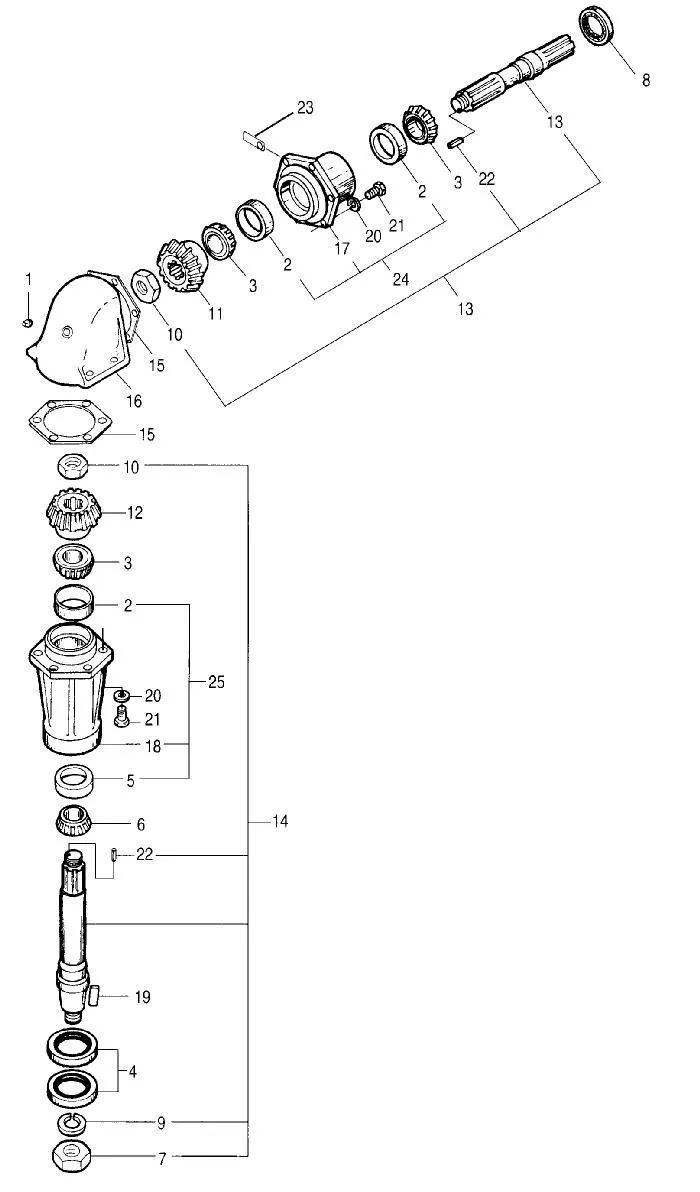

Here are the key components and functions of a Bush Hog gearbox:

Housing

The housing of a Bush Hog gearbox serves multiple purposes. Firstly, it provides structural integrity, enabling the gearbox to withstand the stress and torque generated during operation. It's typically made from materials like cast iron or high-strength aluminum alloys, which offer a good balance between durability and weight. The housing's design also includes provisions for mounting the gearbox securely to the rotary cutter frame and, in some configurations, may incorporate cooling fins to help dissipate heat generated by the internal gears.

Gears

The gears inside a Bush Hog gearbox are central to its operation. They are usually a combination of bevel and spur gears, designed to change the direction of the drive from the tractor's PTO and modify the speed and torque as needed for the cutting blades. These gears are precision-engineered to mesh smoothly, minimizing wear and noise. High-quality, heat-treated steel is often used to withstand the high stresses of cutting through dense vegetation and occasional encounters with rocks or other hard objects.

Input Shaft

The input shaft is directly connected to the tractor's PTO shaft. This connection is crucial for the transfer of power from the tractor to the mower. The shaft typically has a splined design that ensures a tight and secure connection to the PTO, allowing for efficient power transmission. The input shaft's durability is vital, as it must endure constant rotational forces and the shock of engaging and disengaging the PTO.

Output Shaft

Connected to the rotary cutter blades, the output shaft translates the gearbox's internal gear actions into the rotational movement that cuts through vegetation. The design of the output shaft must account for significant torque and potential obstructions that could cause sudden stops or reversals, putting immense stress on the shaft and its connection to the blades.

Bearings and Seals

Bearings within the gearbox reduce friction between the moving parts, contributing to a smoother operation and longer life. They must be robust enough to handle high loads and speeds. Seals are equally important, preventing the ingress of dirt, water, and other contaminants that can cause wear or corrosion inside the gearbox. Proper sealing and bearing design are critical for maintaining optimal lubrication and minimizing maintenance requirements.

Lubrication

The internal components of the gearbox are lubricated with gear oil, which reduces friction, wear, and overheating. The type of oil used can vary based on the gearbox design and the operating conditions, but it typically has high viscosity to provide a durable lubricating film under heavy loads. Regular checking and changing of the gearbox oil are essential maintenance tasks, as contaminated or degraded oil can significantly reduce the lifespan of the gearbox components.

Maintenance and Operation

Proper maintenance of a Bush Hog gearbox involves regular checks of oil levels, inspections for leaks or damage to seals, and listening for unusual noises that might indicate wear or damage to gears or bearings. Additionally, ensuring that the gearbox and rotary cutter are correctly aligned with the tractor's PTO is crucial for minimizing stress and wear on the input shaft.

Understanding these components and their functions highlights the complexity and importance of a Bush Hog gearbox in the overall performance of rotary cutters. Regular maintenance and careful operation are key to leveraging the durability and effectiveness of these powerful agricultural tools.

Types of Bush Hog Gearboxes

Installation and Setup

Installing and setting up a Bush Hog gearbox correctly is crucial for optimal performance and longevity of the rotary cutter. Proper installation ensures efficient power transfer from the tractor to the cutter and helps prevent premature wear or damage. Here's a step-by-step guide to help you through the process:

Read the Manual

- Before starting, thoroughly read the manufacturer's manual for both your tractor and the Bush Hog gearbox. This document contains specific instructions, safety warnings, and tips tailored to your equipment.

Prepare the Equipment

- Gather tools needed for the installation, such as wrenches, pliers, and possibly a torque wrench.

- Inspect the gearbox and mounting area for any shipping damage or defects.

- Verify that you have the correct gearbox model for your rotary cutter.

Align the Gearbox

- Position the gearbox onto the rotary cutter, ensuring that the output shaft is correctly aligned with the cutter's drive mechanism (this might be a direct connection to the blades or through additional drive components).

- Check alignment for any misalignment that could lead to excessive wear or failure.

Mount the Gearbox

- Securely fasten the gearbox to the rotary cutter using bolts, typically provided with the gearbox. Follow the manufacturer's recommended torque specifications to avoid over-tightening or under-tightening.

- Ensure there is no movement between the gearbox and the cutter deck once mounted.

Connect the PTO Shaft

- Attach the PTO shaft from the tractor to the gearbox's input shaft. Ensure that the shaft is correctly sized and that the connection is secure.

- Check that the PTO shaft has the proper length; a shaft that's too long or too short can cause damage when the tractor's hitch is raised or lowered.

Lubricate the Gearbox

- Fill (or check) the gearbox with the appropriate type and amount of oil as specified by the manufacturer. This step is crucial for new gearboxes or if the existing oil has been drained.

- Inspect for any oil leaks around seals and gaskets after filling.

Adjustments and Safety Checks

- Verify that all safety shields and guards are in place and securely attached.

- Test the installation at a low PTO speed in an open area, listening for any unusual noises indicating misalignment or other issues.

- Inspect all connections and fasteners after the initial test run, tightening as necessary.

Maintenance

- Establish a regular maintenance schedule based on the manufacturer's recommendations, including checks for oil levels, bolt tightness, and overall condition of the gearbox and PTO shaft.

Safety First

Throughout the installation process, prioritize safety by ensuring the tractor and rotary cutter are on stable ground, the tractor is turned off with the keys removed, and all moving parts have stopped before making any connections or adjustments.

Properly installing and setting up a Bush Hog gearbox can significantly impact the performance and lifespan of your rotary cutter. By following these steps and adhering to the manufacturer's guidelines, you'll ensure your equipment is ready for efficient and reliable operation.

Maintenance of Bush Hog Gearbox

Maintaining a Bush Hog gearbox is crucial for ensuring the longevity and performance of your rotary cutter. Regular maintenance can prevent breakdowns, extend the life of the gearbox, and ensure it operates efficiently. Here's a comprehensive guide on how to maintain a Bush Hog gearbox:

Regular Inspections

- Check for Leaks: Regularly inspect the gearbox for oil leaks. Leaks can lead to a lack of lubrication, causing the gears to wear out prematurely.

- Inspect Seals and Gaskets: Ensure that seals and gaskets are intact to prevent leaks and contamination of the gearbox oil.

- Look for Damage: Check the gearbox housing for any signs of cracks, dents, or other damage that could affect its integrity.

Oil Level and Quality

- Check Oil Level: Before each use, check the oil level in the gearbox. The oil should be at the level recommended by the manufacturer.

- Change Oil Regularly: Change the gearbox oil at the intervals specified by the manufacturer. Use the type of oil recommended for your specific model.

- Monitor Oil Quality: Look for signs of contamination or degradation in the oil. Contaminants like water or debris can significantly reduce the oil's effectiveness and damage internal components.

Lubrication

- Grease Moving Parts: Regularly grease all external moving parts, such as the PTO shaft and any external bearings, to reduce friction and wear.

- Follow Manufacturer Recommendations: Use the type and amount of grease recommended by the manufacturer for the best protection.

Gear and Bearing Inspection

- Schedule Downtime for Inspection: Periodically, schedule a more thorough inspection of the internal gears and bearings. This may require partially disassembling the gearbox.

- Look for Wear and Damage: Check for any signs of excessive wear, chipped or broken teeth on the gears, and wear or damage to the bearings. Early detection can prevent more significant problems.

Tightening and Adjustments

- Check Bolts and Fasteners: Ensure that all bolts and fasteners are tight and secure. Vibrations from operation can loosen these over time, leading to misalignments or other issues.

- Adjust as Necessary: Follow the manufacturer's guidelines for any needed adjustments to keep the gearbox operating smoothly.

Protective Measures

- Use a Slip Clutch: If not already equipped, using a slip clutch on the PTO shaft can protect the gearbox from shock loads by slipping under excessive resistance.

- Avoid Overloading: Do not exceed the recommended operating capacities of your equipment. Overloading the gearbox can lead to premature failure.

Storage

- Proper Storage: When not in use, store your equipment in a dry, covered area to protect the gearbox from the elements and prevent rust and corrosion.

Record Keeping

- Maintain Records: Keep a log of all maintenance activities, including oil changes, parts replacements, and any repairs. This record can help track the gearbox's health and plan future maintenance.

Following these maintenance steps can help ensure that your Bush Hog gearbox remains in good working condition, providing reliable service for many years. Always refer to your specific gearbox model's manual for detailed maintenance instructions and schedules.