In the intricate world of automotive and machinery, the gearbox stands as a pivotal component, ensuring the seamless transmission of power from the engine to the wheels or operational parts. The cost of a gearbox, influenced by a myriad of factors, can significantly vary.

Understanding Gearboxes

What is a Gearbox?

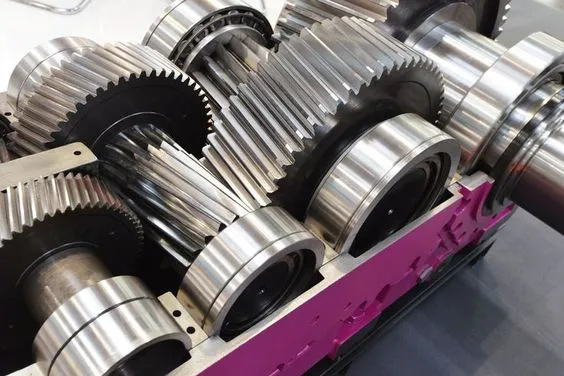

A gearbox is a mechanical unit that utilizes gears and gear trains to provide speed and torque conversions from a rotating power source to another device. It's crucial in automobiles, allowing them to operate efficiently at various speeds. Gearboxes are also vital in various machinery, from simple food mixers to complex industrial equipment.

Types of Gearboxes

The article would delve into the main gearbox types: manual, automatic, semi-automatic, continuously variable transmission (CVT), and industrial gearboxes. Each type has unique advantages, from the manual gearbox's direct driver engagement to the automatic gearbox's convenience and the CVT's efficiency.

Factors Influencing Gearbox Costs

Gearbox costs can be influenced by a variety of factors, ranging from material and manufacturing processes to market demand and technological advancements. Here's a detailed breakdown of some key factors:

Material Costs: The materials used in gearbox construction, such as steel, aluminum, or composite materials, significantly impact the overall cost. High-quality materials that offer durability and longevity tend to be more expensive.

Design Complexity: The complexity of the gearbox design affects the cost. More complex gearboxes, such as those with a higher number of gears or those designed for specific performance requirements, require more engineering effort, precision in manufacturing, and hence, are more costly.

Manufacturing Processes: The cost of manufacturing gearboxes can vary based on the processes involved. Advanced manufacturing techniques like CNC machining, which offers high precision, can increase production costs. Additionally, the cost of labor in the manufacturing location also plays a crucial role.

Scale of Production: Economies of scale can significantly influence gearbox costs. Producing gearboxes in large quantities typically reduces the per-unit cost due to the spread of fixed costs over a larger number of units.

Quality and Performance Specifications: Gearboxes designed to meet higher performance standards or those that require rigorous testing and quality assurance protocols can be more expensive. This includes gearboxes for aerospace, automotive racing, or industrial applications where reliability is critical.

Brand and Warranty: The brand reputation and the warranty offered with the gearbox can also affect its cost. Products from well-established manufacturers with comprehensive warranty and support services are often priced higher.

Market Demand: The demand for specific types of gearboxes in the market can influence their cost. High demand can lead to higher prices, especially if the supply is limited or if the technology is relatively new and in high demand.

Technological Advancements: Investment in research and development for new technologies to improve gearbox efficiency, reduce weight, or incorporate smart technologies for monitoring and control can add to the cost. However, these advancements can also lead to long-term savings in operation and maintenance.

Regulatory and Environmental Standards: Compliance with regulatory and environmental standards can also impact the cost of gearboxes. Manufacturing gearboxes that meet specific environmental standards or certifications can require additional processes and materials, increasing the cost.

Shipping and Logistics: The cost of shipping and logistics, especially for heavy or bulky gearboxes, can significantly add to the overall cost. International shipping and customs duties can further increase the price for overseas customers.

Understanding these factors can help in evaluating gearbox options and making informed decisions based on cost, performance, and application requirements.

Average Cost of Gearboxes

The average cost of gearboxes varies widely depending on their type, size, application, and specific requirements. Here's a general overview of how costs can range across different types of gearboxes:

Automotive Gearboxes: For personal vehicles, the cost of a replacement gearbox can range from $1,500 to $3,000 for manual transmissions and from $2,000 to $4,000 for automatic transmissions. High-performance or luxury vehicle gearboxes can significantly exceed these ranges.

Industrial Gearboxes: Industrial gearboxes, used in machinery for construction, manufacturing, and other heavy-duty applications, can vary significantly in price. Small, standard gearboxes might start around $500, but more specialized or larger capacity gearboxes can easily reach tens of thousands of dollars, with some high-performance or large industrial gearboxes exceeding $100,000.

Wind Turbine Gearboxes: The cost for wind turbine gearboxes, which are large and designed to withstand high loads and environmental conditions, can range from $20,000 to over $300,000 depending on the turbine's capacity and design requirements.

Agricultural Gearboxes: Gearboxes used in agricultural machinery like tractors and harvesters can range from $1,000 to $5,000, with prices varying based on the size and complexity of the machinery.

Marine Gearboxes: For boats and ships, marine gearboxes can cost from $1,000 for small, simple models to over $100,000 for those designed for large vessels or specific performance requirements.

These ranges are approximate and can fluctuate based on factors such as material costs, brand, specific design requirements, and market demand. Additionally, technological advancements and innovations in gearbox design and manufacturing processes can also impact costs over time. For the most accurate and current pricing, it's best to consult with suppliers or manufacturers directly, considering the specific requirements of the application.

Additional Costs to Consider

DIY Repairs and Maintenance

For those inclined towards DIY, there's potential for cost savings in undertaking repairs and maintenance personally. However, this comes with cautionary advice about the risks and the need for appropriate skills and tools.

Choosing the Right Service Provider

Finding a reputable mechanic or service center is vital. This section would offer tips on identifying trustworthy professionals, including what certifications to look for and the right questions to ask.

Warranty and Insurance

Understanding how warranties and insurance might cover gearbox repairs or replacements can also affect costs. This portion would explain the importance of knowing the extent of coverage under these policies.

Real-world Examples

Illustrative examples spanning different scenarios—like replacing a gearbox in an economy car versus a luxury vehicle or industrial equipment—would provide readers with a clearer understanding of the potential costs involved.

The article would conclude by summarizing the critical points covered, reinforcing the importance of understanding the various factors that influence gearbox costs. It would encourage readers to weigh both short-term and long-term considerations in their decision-making process, advocating for informed choices to ensure both cost-efficiency and reliability in their vehicles or machinery.