Maintaining and servicing agricultural equipment is crucial for ensuring efficiency and longevity. One of the more nuanced tasks involves the removal of a Power Take-Off (PTO) shaft from a bush hog gearbox. This detailed guide aims to provide an in-depth approach to this procedure, emphasizing safety, precision, and maintenance practices.

Understanding the Importance of the Task

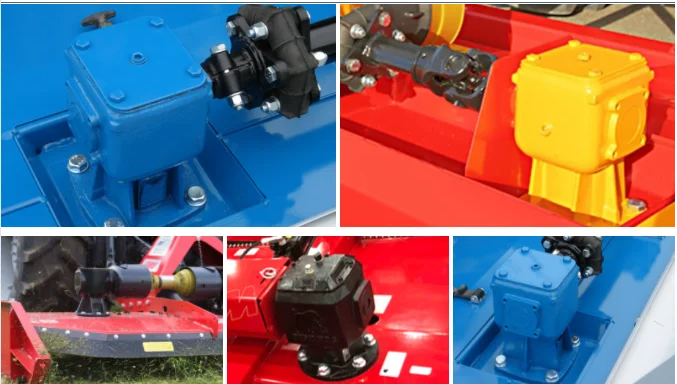

The PTO shaft plays a pivotal role in transmitting power from the tractor to the bush hog, enabling the cutting action necessary for managing vegetation. The bush hog gearbox, on the other hand, translates this power into the rotational force that drives the cutting blades. Proper maintenance of these components is vital for operational efficiency and safety.

Preparatory Steps for Safe and Effective Removal

Safety First

- Disconnect the Power Source: Ensure the tractor's engine is off, the PTO is disengaged, and the keys are removed to prevent accidental startup.

- Stabilize the Equipment: Work on a flat, stable surface. If possible, secure the bush hog to prevent it from moving during the removal process.

Gathering the Right Tools

Assembling the correct tools before you begin is crucial. You'll need:

- A comprehensive wrench set for various sizes of nuts and bolts.

- A hammer for gentle persuasion on stuck components.

- Both flathead and Phillips screwdrivers for different types of securing mechanisms.

- Penetrating oil, such as WD-40, to loosen rusted or stuck parts.

- Safety glasses and durable gloves to protect against debris and sharp edges.

Detailed Removal Process

Step 1: Disconnecting the PTO Shaft from the Tractor

This step requires identifying the specific mechanism that secures the PTO shaft to the tractor—variations exist across models. Once located, carefully release this mechanism. This might involve retracting a pin or lever. With the mechanism released, support the PTO shaft's weight as you slide it off the tractor's stub, ensuring not to damage the spline.

Step 2: Detaching the PTO Shaft from the Bush Hog Gearbox

Focus on the connection point between the PTO shaft and the gearbox. Use penetrating oil on any bolts or pins showing signs of corrosion. After allowing the oil to work, remove the securing elements. It's essential to note the orientation of any components for accurate reassembly. Gently slide the shaft away from the gearbox, taking care not to force it.

Step 3: Inspection and Cleaning Phase

With the shaft removed, inspect both it and the gearbox's input for signs of wear or damage. This is also the perfect time to clean these components. Use a wire brush to remove rust and debris, and apply a lubricant to prevent future corrosion.

Reassembly and Maintenance Insights

Reinstalling the PTO shaft involves reversing the removal steps with additional considerations for maintenance:

- Lubrication: Apply a high-quality lubricant to the shaft and gearbox input. This not only facilitates easier future removals but also protects against wear.

- Secure Fastening: Ensure all bolts, pins, or levers are securely fastened to avoid vibration or detachment during operation.

- Functional Test: After reassembly, conduct a low-speed operational test to identify any issues like abnormal noise or vibration, indicating improper installation.

Advanced Maintenance Tips

- Regular Checks: Incorporate a schedule for inspecting the PTO shaft and gearbox, looking for any signs of undue wear or damage.

- Lubrication Schedule: Adhere to a consistent lubrication schedule, tailored to the frequency of use and the manufacturer's recommendations.

- Replacement Parts: Keep an inventory of essential spare parts for quick replacement of worn components, minimizing downtime.

The removal of a PTO shaft from a bush hog gearbox, while intricate, is a manageable task with careful preparation and attention to detail. This guide provides a foundation, but always refer to your specific equipment's manual for detailed instructions and safety warnings. Regular maintenance and careful handling ensure the longevity and efficiency of your agricultural machinery.

FAQs Expanded

Q: How do I deal with severely rusted components?

A: For components that penetrating oil can't loosen, consider gently heating the area with a torch to expand the metal, making it easier to break the rust bond. Exercise caution to avoid damaging nearby parts.

Q: What signs of wear should I look out for on the PTO shaft?

A: Key wear indicators include splines that are visibly worn down, cracks in the shaft body, and excessive play in any universal joints. Such damage can lead to operational failures and should be addressed immediately.